Last Updated on June 11, 2025 by Admin

In 2022, steel building contractors, erectors, manufacturers, and suppliers will continue to deal with global steel supply chain issues, which can lead to higher costs and project delays. Steel materials input prices (total costs to produce the product) rose 141.6 percent over the past year, and iron and steel input prices increased 105 percent.

ConstructionCareerHub App is LIVE — built ONLY for construction careers. Don’t apply with a weak resume.

Get ATS-ready Resume Lab + Interview Copilot + Campus Placement Prep (resume screening, skill gaps, interview readiness) — in minutes & Other advanced features.

Explore Smarter Construction Career Tools →Quick check. Big impact. Start now.

Contractors’ bids remained essentially stable between 2020 and 2021, while construction input prices soared by 23.5 percent. Builders that delay purchasing products close to the bid time increase the risk of losing their project’s profits and creating severe financial hardship. Here are six tips on avoiding supply chain issues: diversify products, utilize dealer locator software, plan with BIM, lessen fuel costs, expand inventory, and provide transparency and excellent communication to your customers.

Table of Contents

What’s Causing Steel Supply Chain Problems?

The construction industry consumes 50 percent of the world’s total steel, followed by the automotive and manufacturing industries. The success of these industries depends on efficient and reliable supply chains. Unfortunately, supply chain issues due to the pandemic continue to increase steel prices, limit product availability, and impact project delivery time.

The onset of COVID-19 fueled the rise in steel prices. At the beginning of the pandemic, steel demand dropped, primarily due to a slow down in construction projects and shutdowns of car factories. In response, steel manufacturers significantly reduced production. In addition, lockdowns disrupted the supply chains by limiting material delivery to construction sites, delaying project delivery time, and costing money.

Soon after the pandemic started, unexpected demand and the low supply of steel led to rapidly shrinking steel inventories and shipment delays – skyrocketing prices to 300 percent above pre-pandemic levels.

In addition, steel tariffs implemented in 2018 have reduced steel imports to the U.S., contributing further to steel shortages and higher prices.

Unfortunately, experts predict steel prices to remain high due to the immense outpacing of demand vs. supply and the time it will take to replenish depleted domestic steel stockpiles due to America’s aging steel mills.

Six Tips on How Metal Suppliers and Manufacturers Can Avoid Supply Chain Issues

Steel building contractors, erectors, manufacturers, and suppliers can avoid and survive metal supply-chain issues

1. Diversify Products to Reduce Steel Waste

Diversify your product selection to materials that minimize steel use and waste, save money, and help keep your project on schedule. For example, utilizing Steel Building Kits instead of standard steel construction will save on waste, money, and time. For example:

- Precision-cut kit components lessen material costs by minimizing waste.

- Modular-designed buildings allow you to expand or rearrange the parts to accommodate your business’s current needs, eliminating the steel needed to rebuild.

- Prefabricated kits offset the cost of steel since assembling a steel building kit takes 33 percent less time than other building methods, saving time and labor costs.

2. Update your Dealer Locator Software

Dealer locator software aims to maximize manufacturers’ conversion rates by matching website customers with the best local dealers, retailers, and contractors. For aliexpress dropshipping sellers, integrating a dealer locator can offer customers both online sourcing and local pickup options, enhancing trust and convenience. The software, with inventory transparency, will direct your customers to websites that have your product confidently in stock to purchase, which is vital for steel manufacturers dealing with product shortages. In addition, a Shopify store locator efficiently helps customers make their final purchase, critical when competing for limited building supplies, like steel.

3. Plan and Design with BIM

Building information modeling (BIM) helps precisely estimate the amount of steel needed for a project, to reduce waste and save money. BIM combines graphics technology and construction design. It creates a comprehensive visualization of construction projects at every stage in the process, including operation, conceptual design, construction logistics, etc.

4. Reduce Transportation Costs

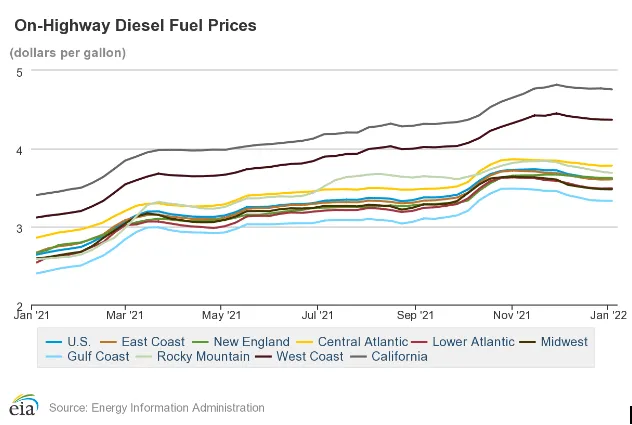

Soaring diesel fuel costs (81 percent over the last 12 months) further increase the cost to transport steel to a job site. Therefore, select the closest distributor to your job site to offset high steel costs and reduce delivery time.

5. Build Up Inventory

Longer lead times due to material shortages increase the risk of higher steel prices cutting into your profits. However, renting storage space and purchasing enough materials to offset product delays will help manage your costs and keep your project on time.

6. Communication and Transparency with Clients

During the bid, communicate honestly about your client’s potential steel delivery lead times. Frequently updating your client about delays and schedules will ease their minds, tremendously improving your customer service, which is essential for future recommendations

How Metal Suppliers and Manufacturers Can Avoid Supply Chain Issues

Metal suppliers, manufacturers, and contractors can avoid steel supply chain issues through planning and product selections that limit steel waste and streamline construction, like steel building kits. In addition, buying and storing steel for future use will help manage fluctuations in steel prices. In addition, providing your customers excellent transparency and communications as lead times change will significantly improve your customer service ratings.

Related Posts:

- 4 Essential Contacts for Construction Professionals

- The Ultimate Guide to Metal Buildings: Everything You Need to Know

- Top Construction Equipment Manufacturers In India [Updated List]

- Best Times In The Year To Rent A Car In Dubai

- Logistics and Supply Chain Management Online Courses For

- Supply Chain Management and Logistics: The Ultimate Career Guide for

- Supply Chain Manager Job description and Salary details