Last Updated on July 28, 2025 by Admin

In civil engineering, many terms and abbreviations are crucial to understand. When discussing moisture control in construction, understanding the DPC full form in civil engineering is fundamental. DPC stands for Damp Proof Course – a critical building component that protects structures from rising damp and moisture damage. This comprehensive guide explores everything you need to know about DPC technology, from traditional methods to cutting-edge 2025 innovations.

ConstructionCareerHub App is LIVE — built ONLY for construction careers. Don’t apply with a weak resume.

Get ATS-ready Resume Lab + Interview Copilot + Campus Placement Prep (resume screening, skill gaps, interview readiness) — in minutes & Other advanced features.

Explore Smarter Construction Career Tools →Quick check. Big impact. Start now.

Table of Contents

Understanding DPC in Civil Engineering

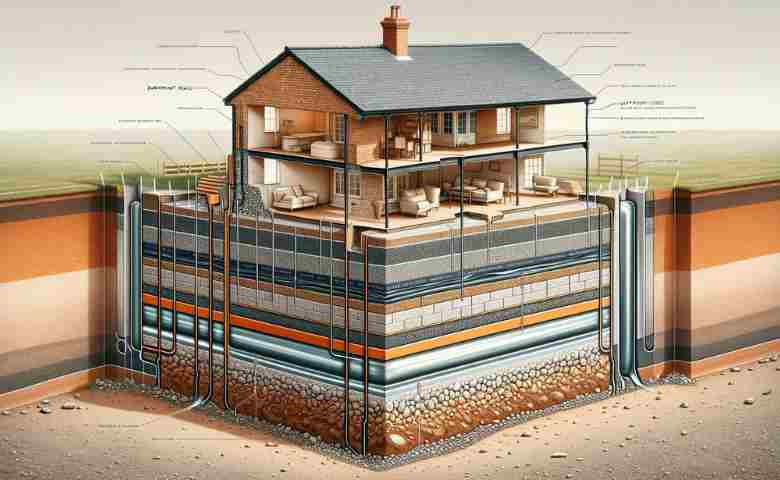

Damp Proof Course (DPC) is a vital component in building construction that aims to prevent the ingress of moisture or dampness into a structure. It acts as a barrier to prevent water from seeping through walls, floors, or foundations. Understanding the definition and importance of DPC is crucial for anyone involved in the civil engineering industry.

Regarding building construction, the role of DPC cannot be overstated. Not only does it protect the structural integrity of a building, but it also ensures the health and safety of its occupants. By effectively blocking the upward movement of moisture, DPC helps in maintaining a dry and healthy indoor environment, free from mold and mildew.

Definition and Importance of DPC

DPC is a layer of waterproof material that is installed horizontally in a building’s structure to prevent rising damp. Rising damp occurs when moisture from the ground travels upwards through the walls, leading to mold growth, decay, and structural damage. A properly installed DPC provides a barrier against this moisture, protecting the building and its occupants. Researching building materials often begins with exploring dpc full form in construction to gain insights into effective damp proofing solutions.

Furthermore, DPC plays a significant role in enhancing the energy efficiency of a building. By preventing moisture ingress, it helps in reducing heat loss through walls and floors, thereby contributing to lower energy consumption and cost savings in the long run.

Different Types of DPC Materials

There are several types of materials used for DPC installation, each with its advantages and disadvantages. Some common materials include:

- Bituminous Felt: A widely used material for DPC due to its durability and affordability.

- Plastic Membrane: Offers excellent flexibility and resistance to moisture.

- Metal Sheets: Provides superior strength and stability but requires skilled installation.

- Chemical DPC: Applied as a liquid or gel, this material forms a barrier that blocks moisture.

Each type of DPC material has specific applications based on factors such as building design, environmental conditions, and budget constraints. It is essential to choose the right type of DPC material during the construction phase to ensure long-term protection against dampness and water ingress.

The Role of DPC in Building Construction

The DPC (Damp Proof Course) is a fundamental component in the construction of buildings, playing a crucial role in safeguarding the structure against moisture and water damage. Its significance extends beyond mere protection, as it contributes to the overall durability and longevity of the building.

One of the key areas where DPC is indispensable is in foundation construction. During this phase, the DPC is meticulously installed between the foundation and the ground. By creating a barrier that inhibits the passage of moisture, the DPC shields the foundation from potential water ingress. This protective layer not only prevents dampness from compromising the structural integrity of the foundation but also helps in maintaining a stable and dry environment within the building.

DPC in Foundation Construction

During foundation construction, DPC is installed between the foundation and the ground to prevent moisture from entering the structure. The DPC acts as a protective layer and ensures the longevity of the building by preventing water damage and preserving the structural integrity of the foundation.

Furthermore, the role of DPC in wall construction is equally significant. When incorporated horizontally between the courses of bricks or blocks, the DPC serves as a continuous barrier against moisture infiltration. By impeding the transfer of dampness from the ground to the internal sections of the wall, the DPC plays a pivotal role in maintaining the dryness and integrity of the walls. This proactive measure not only averts potential issues like mold growth and material deterioration but also enhances the overall resilience of the building structure.

DPC in Wall Construction

In wall construction, DPC is installed horizontally between the courses of bricks or blocks. It forms a continuous barrier that prevents moisture from transferring from the ground to the internal parts of the wall. By blocking the passage of dampness, DPC ensures the walls remain dry, thus avoiding issues such as mold growth and deterioration.

The Process of Installing DPC

Proper installation of DPC (Damp Proof Course) is crucial for maintaining the structural integrity and longevity of a building. DPC acts as a barrier to prevent moisture from rising through walls and causing dampness. Let’s delve deeper into the intricacies of the installation process to ensure a successful outcome.

Before embarking on the installation of DPC, thorough pre-installation considerations must be made to guarantee effectiveness. Site conditions play a pivotal role in determining the type of DPC material best suited for the specific environment. Factors such as ground water levels, soil composition, and proximity to water sources need to be evaluated. Additionally, the selection of the appropriate DPC material, whether it be polyethylene, bitumen felt, or chemical injection, is crucial for optimal performance. Calculating the required length of DPC is essential to ensure complete coverage and protection against moisture ingress. Adequate preparation of the surface is also paramount, involving the meticulous removal of any obstructions or debris that could compromise the integrity of the DPC.

Step-by-step Installation Procedure

The installation procedure for DPC is a meticulous process that demands attention to detail and precision. Following a structured approach ensures the effectiveness of the damp proofing system:

- Begin by thoroughly cleaning and leveling the surface where the DPC will be installed, ensuring a smooth and even foundation for the barrier.

- Measure and cut the DPC material to the required length with precision, ensuring that it extends sufficiently beyond the walls or foundation to provide comprehensive protection.

- Securely fix the DPC material in place using appropriate fixing methods such as mechanical fixings or adhesives, ensuring a tight seal against the substrate.

- Pay special attention to overlapping joints, ensuring they are meticulously sealed to create a continuous and impermeable barrier against moisture infiltration.

- Thoroughly inspect the entire installation for any gaps, tears, or defects that could compromise the effectiveness of the DPC. Any identified issues should be promptly rectified to maintain the integrity of the damp proofing system.

- Upon successful installation of the DPC, it is imperative to protect it during subsequent construction stages to prevent accidental damage or displacement. Safeguarding the DPC ensures its long-term functionality and the preservation of the building’s structural integrity.

Common Problems and Solutions with DPC

Despite the effectiveness of DPC, problems can arise that may compromise its performance. Identifying these issues and implementing effective remedies is crucial in maintaining a moisture-free environment.

Ensuring the proper installation of Damp Proof Course (DPC) is essential in preventing water ingress and dampness in buildings. DPC is typically a physical barrier made of materials like bitumen felt, plastic sheets, or chemical compounds that are installed horizontally between different elements of a building to prevent moisture from rising through capillary action.

Identifying DPC Issues

Problems with DPC can manifest in various ways, including water stains, peeling paint, musty odors, and visible signs of mold or decay. It is important to identify these issues early on to prevent further damage to the building structure.

In older buildings, DPC may have deteriorated over time due to factors such as poor maintenance, ground movement, or incorrect installation. This deterioration can lead to the failure of the DPC, allowing moisture to penetrate the walls and causing issues like rising damp or fungal growth.

Effective Remedies for DPC Problems

Addressing DPC problems may involve solutions such as repairing or replacing damaged DPC sections, improving drainage systems, conducting regular inspections, and implementing appropriate ventilation measures. Consulting with a qualified professional is advisable to determine the most suitable course of action for each specific problem.

In cases where rising damp is a concern, installing a chemical DPC injection can be an effective solution. This process involves injecting a chemical damp-proofing fluid into the walls at regular intervals to create a barrier against moisture rising from the ground. Additionally, ensuring that the external ground levels are lower than the internal floor levels can help prevent water from seeping into the building through the walls.

Future Trends and Sustainability

The future of DPC technology is shaped by environmental concerns, technological advancement, and changing construction practices.

Sustainable Materials and Manufacturing

Recycled Content Materials

- Post-consumer plastic DPC: Manufactured from 100% recycled materials

- Bio-based polymers: Renewable feedstock alternatives to petroleum products

- Circular economy integration: Design for end-of-life recyclability

Low-Carbon Manufacturing

- Reduced energy production: Optimized manufacturing processes

- Local sourcing: Minimizing transportation carbon footprint

- Life cycle assessment: Comprehensive environmental impact evaluation

Climate Change Adaptation

Enhanced Performance Requirements

- Extreme weather resilience: DPC systems designed for increased precipitation

- Flood resistance: Enhanced protection against groundwater infiltration

- Temperature extremes: Materials suitable for wider operating ranges

Smart Building Integration

- Building Management Systems: DPC monitoring integrated with HVAC control

- Predictive maintenance: AI-driven performance optimization

- Energy efficiency: Moisture control contribution to thermal performance

Research and Development Trends

Advanced Materials Research

- Graphene applications: Revolutionary strength and impermeability

- Self-healing materials: Autonomous repair of minor damage

- Multifunctional systems: Combined moisture control and thermal insulation

Digital Construction Integration

- BIM modeling: 3D visualization of DPC systems in design phase

- Digital twins: Virtual monitoring of DPC performance

- Automated installation: Robotic application systems for consistent quality

Advanced DPC Technologies in 2025

The construction industry continues to evolve with innovative damp proofing solutions that address modern challenges including climate change, sustainability, and smart building integration.

Electromagnetic DPC Systems

Magnetic damp proof courses utilize electromagnetic fields to influence moisture behavior:

- Zero chemical impact: Environmentally safe installation and operation

- Heritage building compatibility: No structural alteration required

- Continuous operation: 24/7 moisture control without maintenance

- Proven performance: Field testing shows significant moisture reduction

Nanotechnology Applications

Research into nanomaterial DPC solutions shows promising developments:

- Graphene-enhanced membranes: Superior strength and impermeability

- Self-healing polymers: Automatically repair minor damage

- Ultra-thin barriers: Minimal impact on construction dimensions

Smart Integration Features

Modern DPC systems increasingly incorporate IoT (Internet of Things) capabilities:

- Moisture sensors: Real-time monitoring of DPC performance

- Alert systems: Early warning of potential moisture breakthrough

- Data analytics: Long-term performance tracking and optimization

Final Reflections

Understanding the DPC full form in civil engineering and its critical role in building protection is essential for construction professionals in 2025. As technology advances, DPC systems continue to evolve with sustainable materials, smart monitoring capabilities, and enhanced performance characteristics.

Effective damp proofing requires careful material selection, professional installation, and ongoing maintenance. With proper implementation, modern DPC systems provide decades of reliable moisture protection, contributing to building longevity, occupant health, and energy efficiency.

For construction professionals seeking to specify the most appropriate DPC solutions, consulting with qualified structural engineers and following current building standards ensures optimal performance and regulatory compliance.

Expert FAQs

What does DPC stand for in construction?

DPC stands for Damp Proof Course – a waterproof barrier installed in buildings to prevent moisture infiltration through walls and foundations. Understanding the DPC full form in civil engineering is essential for construction professionals.

How long do modern DPC systems last?

Quality DPC materials typically last 25–50 years depending on the material type and installation quality. Traditional bituminous products last 15–20 years, while modern polymer systems can exceed 50 years with proper installation.

Can DPC be installed in existing buildings?

Yes, chemical injection DPC is specifically designed for retrofit applications in existing buildings. This method involves injecting waterproofing chemicals into the wall structure to create an effective moisture barrier.

What are the signs of DPC failure?

Common indicators of DPC failure include rising damp stains, peeling paintwork, salt deposits on walls, musty odors, and deteriorating plaster, typically appearing within 1 meter of ground level on internal walls.

Related Posts:

- All You want to know about Construction Equipment Financing

- Thermal Bridging: Everything you need to know about

- The Environments Best Suited for Corrosion Protection

- Mastering the Basics: Foundation Civil Engineering Explained

- What Makes Concrete Barriers a Good Choice for Urban Construction Zones?