Last Updated on October 14, 2024 by Admin

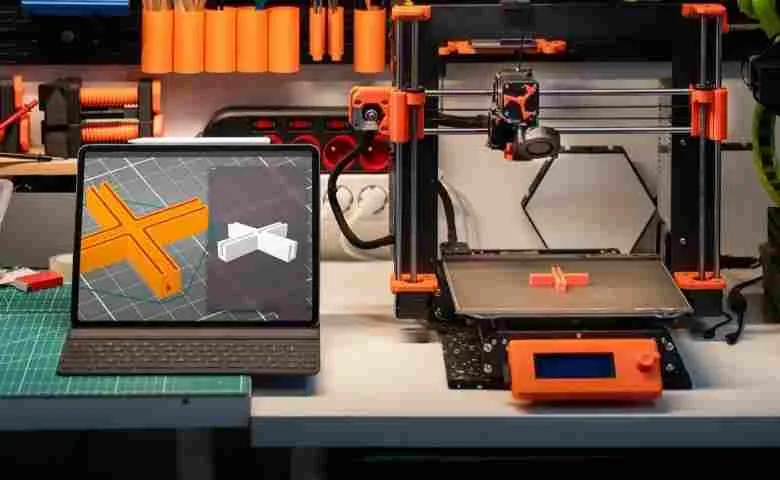

Both injection molding and 3D printing are popular manufacturing methods for making parts and products – but which is best for your business?

ConstructionCareerHub App is LIVE — built ONLY for construction careers. Don’t apply with a weak resume.

Get ATS-ready Resume Lab + Interview Copilot + Campus Placement Prep (resume screening, skill gaps, interview readiness) — in minutes & Other advanced features.

Explore Smarter Construction Career Tools →Quick check. Big impact. Start now.

Let’s take a look at each of the manufacturing processes in detail – you will then be able to better discern which option is right for your specific requirements.

Image source: https://www.pexels.com/photo/3d-print-project-19149826/

Injection Molding

Injection molding is a highly efficient manufacturing process that is widely embraced across various industries. In essence, it involves injecting molten material, such as plastic or metal, into a mold under high pressure.

Injection molding has numerous advantages that make it an attractive option for manufacturers – for example, it is known for its high levels of accuracy and detail. The end products often need little to no finishing work, saving both cost and time.

Also, this method is exceptionally versatile. It can be used to create components of all shapes and sizes. From medical equipment parts to automobile components – the possibilities are virtually endless.

Several industries benefit from injection molding due to these advantages. The automotive industry is a major user of this technique – so too are the health sector and the consumer electronics industry, where precision parts are key.

Businesses requiring mass production of intricate parts could find injection molding particularly beneficial – not forgetting start-ups that are looking to prototype new products cheaply and quickly.

In conclusion, injection molding offers immense value with its high productivity rate, versatility, and usability – making it a popular choice across multiple sectors.

3D Printing

3D printing, also known as additive manufacturing, is a process where a three-dimensional object is created from a digital model. This occurs by stacking successive layers of material until the entire object takes shape.

The advantages of 3D printing are numerous. For one, it allows for much greater complexity in design compared to traditional manufacturing methods. This flexibility opens up vast potential for innovation and customization.

In addition, 3D printing can often be more cost-efficient for small-run productions due to lower startup costs. Not only that, but it creates less waste – which is beneficial both environmentally and economically.

As with injection molding, 3D printing is used by various industries. It is particularly popular in sectors such as aerospace and healthcare, due to its ability to create complex parts quickly.

From startups looking for cost-effective prototyping solutions to larger corporations wanting more flexible manufacturing processes, many businesses could find value in 3D printing.

The process’s distinctive ability to turn ideas into tangible products quickly makes it an impressive tool across different fields. In essence, 3D printing marries innovation with efficiency – a combination that fuels its wide appeal.

Things to Look for When Choosing an Injection Molding or 3D Printing Service

Outsourcing your injection molding or 3D printing needs can be cost-effective and time-saving, allowing for focus on other vital business areas. But what should you look for when selecting a service?

Firstly, consider the technological capabilities of a service – you need to ensure that the company you pick can deliver precisely what you require. Quality control is another key aspect. A provider with stringent quality checks ensures that your products meet the highest standards.

Lastly, when you get an injection molding quote or 3D printing estimate, make sure it provides value for money while also reflecting a top-notch service. Selecting a reliable provider will not only assure quality but also foster long-term collaborative success.

Which Is the Best Option for Your Business?

Choosing between injection molding or 3D printing for your business hinges on various factors. For mass production of detailed, robust parts, injection molding may be the ideal choice.

Conversely, for small quantities of complex, custom parts or prototypes, 3D printing could offer a more cost-effective solution.

It ultimately depends on your specific needs and objectives – there is no one-size-fits-all answer. So, consider your specific needs and research each method in more detail to determine which is the best option for your business.

Related Posts:

- How 3D Printing Is Revolutionizing The Construction Industry

- The Evolution of BIM Technology: A Comprehensive Guide to the Latest Trends and Reports in 2023

- Top 27 Emerging Trends In Construction Technology To Watch In 2024

- 10 Essential Steps in Restoring a Home After Water Damage