Last Updated on August 16, 2024 by Admin

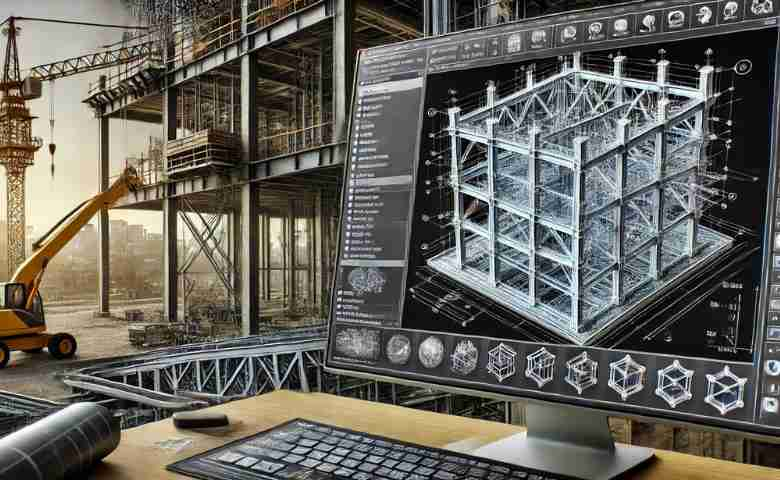

Structural steel detailing is a critical phase in the construction process, where detailed drawings and plans are prepared to guide the fabrication and erection of steel structures. These services ensure steel structures are built accurately, safely, and efficiently. As a specialized service within the broader construction industry, structural steel detailing requires precision, expertise, and a deep understanding of engineering principles.

ConstructionCareerHub App is LIVE — built ONLY for construction careers. Don’t apply with a weak resume.

Get ATS-ready Resume Lab + Interview Copilot + Campus Placement Prep (resume screening, skill gaps, interview readiness) — in minutes & Other advanced features.

Explore Smarter Construction Career Tools →Quick check. Big impact. Start now.

This article provides a comprehensive overview of structural steel detailing services, covering their importance, processes, technologies, and role in the global construction industry.

Table of Contents

What is Structural Steel Detailing?

Structural steel detailing involves creating detailed drawings for steel fabricators and erectors. These drawings encompass plans, elevations, sections, and connection details that guide the manufacturing and assembly of steel members like beams, columns, braces, trusses, and other steel structure components.

Key Components of Steel Detailing

Shop Drawings: Shop Drawings are detailed plans that indicate the specifications for individual steel members. They include information such as dimensions, material specifications, welding details, and painting instructions. Fabricators use these drawings to cut, drill, and weld the steel members.

Erection Drawings: These drawings provide instructions for the on-site assembly of steel members. Erection drawings detail the placement of each steel component, specifying how each part fits within the overall structure. They include information on member positions, bolting, and welding sequences.

Connection Details: These drawings focus on the connections between different steel members, ensuring each connection is designed to withstand the loads and forces it will encounter.

The Importance of Structural Steel Detailing Services

Structural steel detailing is vital for several reasons:

Accuracy and Precision: The detailed drawings ensure that every steel component is fabricated and installed correctly, minimizing errors that can lead to costly delays or structural failures.

Safety: Accurate detailing ensures that the structure will be safe and stable, preventing issues that could compromise its integrity.

Cost Efficiency: By providing clear and detailed instructions, steel detailing helps avoid material wastage, reduces labor costs, and shortens the construction timeline.

Compliance with Standards: Steel detailing services ensure that the structure complies with all relevant building codes and industry standards, which is crucial for the approval of construction projects.

The Structural Steel Detailing Process

The structural steel detailing process involves several steps, each requiring expertise and attention to detail.

1. Gathering Project Information

The first step in the detailing process is to gather all necessary project information, including architectural and engineering drawings, design specifications, and building codes. This information provides the foundation for creating accurate steel detail drawings.

2. Creating the Detailed Drawings

Using specialized software, detailers create shop drawings, erection drawings, and connection details. This step involves translating the design specifications into detailed instructions for fabricators and erectors. The drawings are developed with a focus on accuracy, ensuring that every aspect of the steel structure is accounted for.

3. Coordination with Other Disciplines

Structural steel detailers work closely with architects, engineers, and other construction professionals to ensure that the steel detailing is integrated seamlessly with other aspects of the project. This coordination is essential to avoid clashes and ensure the steel structure supports the overall design intent.

4. Review and Approval

Before fabrication begins, engineers and other stakeholders must review and approve the detailed drawings. This step ensures that the drawings meet all technical requirements and adhere to the project’s specifications.

5. Fabrication and Erection

Once the drawings are approved, they are sent to the fabricators, who cut, drill, weld, and paint the steel components according to the specifications. The erection drawings then guide the on-site assembly of the steel structure.

Technologies Used in Structural Steel Detailing

The evolution of technology has greatly impacted the field of structural steel detailing, enhancing its accuracy and efficiency.

1. Computer-Aided Design (CAD)

CAD software has long been a staple in steel detailing, allowing detailers to create precise 2D drawings. Modern CAD tools are equipped with features that simplify the creation of complex details and facilitate the production of high-quality drawings.

2. Building Information Modeling (BIM)

BIM technology has revolutionized the construction industry, including steel detailing. BIM enables the creation of 3D models that integrate all aspects of a building’s design, including steel structures. With BIM, detailers can visualize the steel structure in three dimensions, identify potential clashes, and ensure the steel components fit perfectly within the overall design.

3. Tekla Structures

Tekla Structures is a specialized BIM software widely used in structural steel detailing. It allows detailers to create highly detailed 3D models of steel structures with all the necessary information for fabrication and erection. Tekla Structures supports the entire workflow, from concept to fabrication, ensuring smooth and efficient detailing.

4. Automated Detailing Software

In addition to BIM, other automated detailing software tools like SDS/2 and AutoCAD Advance Steel have become integral to the detailing process. These tools offer advanced features such as automated connection design, material list generation, and clash detection, further improving the efficiency and accuracy of steel detailing.

The Global Role of Structural Steel Detailing Services

Structural steel detailing services play a critical role in the global construction industry. The demand for these services is driven by the increasing complexity of modern structures, the need for cost-effective construction solutions, and the growing emphasis on safety and compliance.

1. Industrial and Commercial Projects

Structural steel is a primary material for constructing industrial plants, warehouses, and commercial buildings. Steel detailing services are essential for ensuring that these structures are built to exact specifications, capable of withstanding the demands of heavy machinery, and complying with safety regulations.

2. Infrastructure Development

Steel detailing is also crucial in developing infrastructure projects such as bridges, highways, and airports. These projects require detailed engineering and precise execution, both facilitated by high-quality steel detailing services.

3. High-Rise Buildings

The construction of high-rise buildings relies heavily on structural steel due to its strength and versatility. Steel detailing services ensure that these buildings are constructed with the utmost precision and capable of supporting significant loads while maintaining architectural integrity.

4. Global Collaboration

Steel detailing services in today’s globalized construction industry often involve collaboration across multiple countries. Detailers may work with architects and engineers worldwide, necessitating a high level of coordination and communication. Advances in technology, particularly BIM, have made it easier to collaborate on international projects, ensuring that steel detailing services meet the standards and requirements of different regions.

Challenges in Structural Steel Detailing

While structural steel detailing is a highly specialized and crucial service, it has its challenges.

1. Complexity of Designs

Modern architectural designs are becoming increasingly complex, requiring detailers to manage intricate geometries and connections. This complexity can lead to challenges ensuring that all components fit together seamlessly.

2. Tight Deadlines

Construction projects often operate under tight deadlines, putting pressure on detailers to produce accurate drawings quickly. Balancing speed with accuracy is a constant challenge in the detailing process.

3. Coordination with Multiple Stakeholders

Steel detailers must coordinate with various stakeholders, including architects, engineers, fabricators, and erectors. Ensuring everyone is on the same page can be challenging, especially in large or international projects.

4. Adherence to Standards

Different regions have different building codes and standards, which can complicate the detailing process for projects that span multiple countries. Detailers must ensure that their drawings comply with all relevant standards, which requires a deep understanding of local and international regulations.

The Future of Structural Steel Detailing

Technological advances, including further developments in BIM, automation, and artificial intelligence (AI), will likely shape the future of structural steel detailing. These technologies can potentially enhance steel detailing services’ accuracy, efficiency, and safety.

1. AI and Machine Learning

AI and machine learning could significantly automate parts of the detailing process, such as connection design and clash detection. These technologies could help detailers identify potential issues early in the design process, reducing errors and improving the overall quality of the final product.

2. Enhanced Collaboration Tools

As global collaboration becomes more common, new tools and platforms will likely emerge to facilitate communication and coordination across borders. These tools will enable detailers to work more efficiently with stakeholders worldwide, ensuring that steel detailing services meet the highest standards of quality and precision.

3. Sustainable Design

With the construction industry increasingly focused on sustainability, steel detailing services will need to adapt to new requirements and standards related to environmental impact. This may involve incorporating sustainable materials, designing for energy efficiency, and minimizing waste in the fabrication and erection processes.

Conclusion

Structural steel detailing services are an indispensable part of the construction process. They provide detailed drawings and plans to fabricate and erect steel structures with precision and safety. As the construction industry continues to evolve, the role of steel detailing services will become even more critical, driven by technological advances, the complexity of modern designs, and the global nature of construction projects.

By understanding the importance, processes, and challenges of structural steel detailing, stakeholders in the construction industry can better appreciate the value of these services and their role in delivering high-quality, cost-effective, and safe structures worldwide. Whether you’re a construction professional, engineer, or someone interested in the field, a solid grasp of structural steel detailing is essential to navigating the modern construction landscape.

Related Posts:

- Tekla Detailer Job Description, Career Guide, and Salary Insights

- Exploring the Role of Structural Design in Civil Engineering: A Comprehensive Guide

- How to Create a Construction Plan: An Ultimate Guide

- Comprehensive List of the Civil Engineering Software Courses for 2024