Last Updated on December 12, 2025 by Admin

America’s infrastructure — from bridges and dams to highways, railways, energy grids and water pipelines — is showing its age. The American Society of Civil Engineers (ASCE) gives the nation a C– grade, and high-profile collapses have highlighted vulnerabilities. The federal government is pouring resources into revitalization through the $1.2 trillion Infrastructure Investment and Jobs Act (IIJA), while agencies like the Federal Highway Administration (FHWA), Department of Transportation (DOT) and Federal Emergency Management Agency (FEMA) push for modern asset management.

ConstructionCareerHub App is LIVE — built ONLY for construction careers. Don’t apply with a weak resume.

Get ATS-ready Resume Lab + Interview Copilot + Campus Placement Prep (resume screening, skill gaps, interview readiness) — in minutes & Other advanced features.

Explore Smarter Construction Career Tools →Quick check. Big impact. Start now.

Infrastructure monitoring companies harness artificial intelligence (AI), IoT sensors, digital twins, drones and satellite data to deliver real-time health insights. For example, a FHWA research program used mixed-reality headsets and machine-learning algorithms to identify bridge cracks in real time. This guide profiles 15 innovators transforming infrastructure monitoring in 2025 and helps U.S. asset owners choose the right partners.

Table of Contents

Market Overview

Rising Investment in Monitoring

The market for structural health monitoring and digital infrastructure monitoring is booming. The IIJA, state funding programs and private capital are driving a new wave of investment in sensors, AI analytics and cloud platforms. McKinsey estimates that digital twins — virtual replicas of physical assets connected to real-time data — can improve capital and operational efficiency by 20–30%. Federal agencies such as the FHWA, DOT and NOAA support research into AI-enabled inspections, while the 2024 FAA Reauthorization Act established the Drone Infrastructure Inspection Grant (DIIG) program to accelerate UAV adoption.

Technology Drivers: AI, IoT, Digital Twins, Drones and Satellites

Advances in sensors and computing underpin the rise of smart infrastructure technology. IoT devices collect vibration, strain, temperature and environmental data; cloud dashboards aggregate and analyse this information; and machine-learning algorithms detect anomalies and predict maintenance needs. Digital twins merge 3D models with live sensor feeds to create “evergreen” models.

Drones with cameras, LiDAR and thermal imaging reduce inspection costs by as much as 75% compared with traditional methods according to Inside Unmanned Systems. Satellite radar and synthetic aperture radar (SAR) can detect underground moisture and ground movement, while robotics and smart meters enable predictive maintenance on electrical grids as highlighted by Enlit World.

Lessons from Recent Failures

The urgency is heightened by recent collapses. In March 2024, the cargo ship Dali struck a support tower of Baltimore’s Francis Scott Key Bridge, causing the bridge to collapse and disrupting a critical shipping channel according to this Congressional Research Service report. Two years earlier the Fern Hollow Bridge in Pittsburgh failed due to extensive corrosion and ignored maintenance recommendations as detailed by the NTSB investigation. These tragedies underscore the need for continuous monitoring, proactive maintenance and robust protective measures.

15 Companies Revolutionizing Infrastructure Monitoring

1. Bentley Systems

Bentley Systems is a leader in digital twin and infrastructure engineering software. Its iTwin IoT platform combines 3D models with live data from sensors and edge devices to create evergreen digital twins for bridges, tunnels, dams and other assets.

The system integrates diverse sensors and provides dashboards and analytics for dams, mines, construction sites, roads, railways and bridges through Bentley Infrastructure IoT.

Yuba Water Agency uses Bentley’s iTwin IoT to modernise monitoring at California’s New Bullards Bar Dam, improving safety and operational efficiency. By connecting disparate data sources into a single digital twin, Bentley enables asset owners to predict problems, extend asset life and support regulatory compliance.

2. Trimble

Trimble offers automated, continuous monitoring solutions for construction, transportation and energy projects. Its systems use robotic total stations, global navigation satellite systems (GNSS) and geotechnical sensors to track movement in real time.

The Trimble 4D Control (T4D) software consolidates data from these sensors into a single dashboard for analysis and alerts. Trimble also partnered with Worldsensing to integrate a GNSS Meter with T4D, enabling long-term, high-precision 3D movement monitoring in mining, construction and civil infrastructure.

This combination of geodetic and geotechnical monitoring helps detect subtle shifts, landslides or subsidence that may threaten roads, bridges or tunnels.

3. Siemens Infrastructure (Railigent)

Siemens Mobility’s Railigent® suite, part of the MindSphere IoT operating system, delivers smart monitoring and predictive maintenance for rail infrastructure.

The platform provides Smart Monitoring to show the real-time state and location of vehicles, Smart Data Analytics to perform root-cause analysis and remote diagnostics, and Smart Prediction to prescribe maintenance actions.

Transit systems in Atlanta and Charlotte are early adopters, using Railigent to collect data and improve operations. By bringing rail assets into a connected digital ecosystem, Siemens helps operators reduce downtime, enhance safety and optimise energy consumption.

4. DroneDeploy

DroneDeploy is best known for its drone-based progress tracking and site documentation platform. In January 2025 the company received nationwide U.S. Beyond Visual Line of Sight (BVLOS) approval, allowing fully autonomous drones to monitor large sites without pilots.

Its AI-powered platform tracks construction progress in real time, accelerating timelines and improving safety. DroneDeploy reports that its tools are used by more than 80% of the top 50 U.S. general contractors. For construction technology applications, the platform helps teams measure earthwork volumes, document installation of equipment and share updates with stakeholders.

5. Skydio

Skydio manufactures autonomous drones designed for infrastructure inspection. Its drones use six cameras and AI navigation to fly close to structures and capture photogrammetry, video and thermal data without GPS.

Skydio claims that inspections can be completed in half the time and cost of manual methods, and that 43 of 50 state transportation agencies in the U.S. use its drones for bridge inspections.

The company’s AI-driven workflows produce high-resolution digital twins and enable inspectors to safely access hard-to-reach areas. Training times are also reduced because the system handles navigation and obstacle avoidance autonomously.

6. Orbital Insight (Privateer)

Orbital Insight, now part of Privateer, provides AI-powered geospatial analytics. The company’s GO platform combines satellite imagery, radar and other sensor data to detect anomalies such as changes in infrastructure, traffic patterns or land use.

In 2022 Orbital Insight partnered with ASTERRA to integrate Polarimetric Synthetic Aperture Radar (PolSAR) data, which can detect soil moisture beneath surfaces. This combination aims to reveal underground water, chemical leaks and erosion that threaten dikes, levees, rail and mining infrastructure. Asset owners can use these insights to prioritise inspections and repair work.

7. Worldsensing

Worldsensing specialises in LoRa®-based connectivity for remote monitoring of civil infrastructure. The company operates more than 3,000 deployed networks across 70 countries and monitors over 170,000 sensors.

Its wireless devices collect data from geotechnical, geospatial, structural, environmental and process sensors and stream it to information systems. Worldsensing offers single-net and multi-net solutions that provide long-range communication and low power consumption.

By enabling end-to-end connectivity, the company allows mining operations, construction sites, dams and tunnels to monitor deformation, water levels, temperature and vibrations without installing extensive cabling.

8. NevadaNano

NevadaNano develops advanced gas-sensing systems for emissions monitoring. Its MethaneTrack™ 2.0 platform, announced in November 2025, is a next-generation methane emission detection and management solution used by major oil and gas companies across 22 countries.

MethaneTrack 2.0 automates leak detection and repair (LDAR) programs, offering variable leak rate reporting, field data entry, automated reporting and support for hydrogen-blend gas systems.

The system uses proprietary algorithms to reduce power consumption, extend battery life and improve precision under extreme conditions. NevadaNano’s platform is SOC 2 certified and recognised by AT&T’s Gigaton initiative for enabling emissions reductions.

9. Pure Technologies (Xylem)

Pure Technologies, part of Xylem, provides pipeline condition assessment and monitoring solutions. Its SoundPrint® Acoustic Fiber Optic (AFO) system delivers continuous, real-time monitoring of prestressed concrete cylinder pipe (PCCP) by detecting wire breaks.

The system alerts utilities when prestressing wires snap, signalling that the pipe’s structural integrity is weakening. Pure Technologies has monitored more than 830 miles of PCCP and completed 450 proactive repairs; by combining electromagnetic inspections with 24/7 monitoring, utilities can extend the life of critical pipelines and reduce risk.

Case studies show that this data-driven approach can save over 70% compared with full pipeline replacement. In addition to AFO, Pure’s SmartBall® and PipeDiver® tools perform leak detection and wall thickness analysis.

10. Geosense

Geosense is an award-winning manufacturer of sensors for geotechnical and structural monitoring. With more than 30 years of experience and projects in over 100 countries, Geosense specialises in vibrating wire and microelectromechanical systems (MEMS) inclinometers.

The company’s product portfolio includes strain gauges, extensometers, pressure cells, displacement transducers and piezometers. Geosense sensors are used in tunnels, dams, bridges, retaining walls, deep foundations and mining operations.

By manufacturing its products in-house, Geosense ensures quality and customisation. Its sensors integrate with data loggers and telemetry units to provide continuous monitoring of deformation, settlement and pore water pressure.

11. MonitorIQ (GroundProbe)

MonitorIQ is GroundProbe’s geotechnical analysis software for monitoring slope stability and infrastructure movement. The software offers a dual-radar view that allows analysts to display and compare data from two radars, along with exceptional visualisation tools such as front, plan and digital terrain model (DTM) views.

It provides 3D georeferencing, data and image co-registration, and precision-atmospherics noise reduction. MonitorIQ also includes collapse forecasting using inverse-velocity algorithms and rich charting tools. GroundProbe’s radar sensors and MonitorIQ are deployed in mines, tailings storage facilities and civil engineering projects worldwide.

12. Structural Monitoring Systems (SMS)

Structural Monitoring Systems (SMS) develops Comparative Vacuum Monitoring (CVM™) sensors for crack detection and structural health monitoring. CVM is the first Federal Aviation Administration (FAA)-approved sensor for airframe crack detection on certain Boeing 737 aircraft.

The technology provides accurate, reliable, in-situ monitoring of structural integrity for airframes, civil infrastructure, bridges, mining equipment and pipelines. CVM sensors use vacuum channels to detect minute crack growth and can be integrated into remote, automated non-destructive testing systems.

By offering predictive and continuous monitoring, SMS helps asset owners avoid catastrophic failures and reduce inspection costs.

13. OpenSpace

OpenSpace offers an AI-powered construction progress tracking platform that uses 360° cameras and machine learning to produce near-real-time site imagery. Its progress tracking tool processes site imagery in about 15 minutes and tracks more than 700 visual components across over 200 tasks.

A combination of AI and human reviewers creates a detailed record of percent complete, planned-versus-actual progress and milestone tracking.

Spotlights, an early-warning feature, highlight areas at risk of falling behind. OpenSpace integrates with project-management tools and acts as a “single source of truth” for owners, contractors and subcontractors.

14. Intelliwave Technologies (SiteSense)

Intelliwave’s SiteSense platform delivers real-time materials and equipment management for construction and industrial projects.

The web-based software and mobile app use barcode, RFID, Bluetooth Low Energy (BLE) and GPS sensors to track materials, equipment and tools. Users can view material quantities, location and status, schedule deliveries and create work packages, while role-based permissions ensure secure access.

SiteSense also tracks equipment location and maintenance tasks, improving utilisation and reducing downtime. Integration with enterprise resource planning (ERP) systems and project-management software provides a seamless workflow.

15. ASTERRA

ASTERRA uses PolSAR satellite data to monitor underground moisture and detect leaks in water and wastewater infrastructure. The technology, formerly known as Utilis, processes radar signals to identify soil moisture anomalies beneath surfaces.

In partnership with Orbital Insight, ASTERRA’s data is combined with AI-powered geospatial analytics to detect underground water, chemical leaks and erosion in dikes, levees, rail and mining infrastructure.

Water utilities and public agencies use ASTERRA’s solutions to find hidden leaks, prioritise pipe replacement and reduce non-revenue water. By analysing satellite imagery across broad regions, ASTERRA can pinpoint problems that ground-based sensors or manual inspections miss.

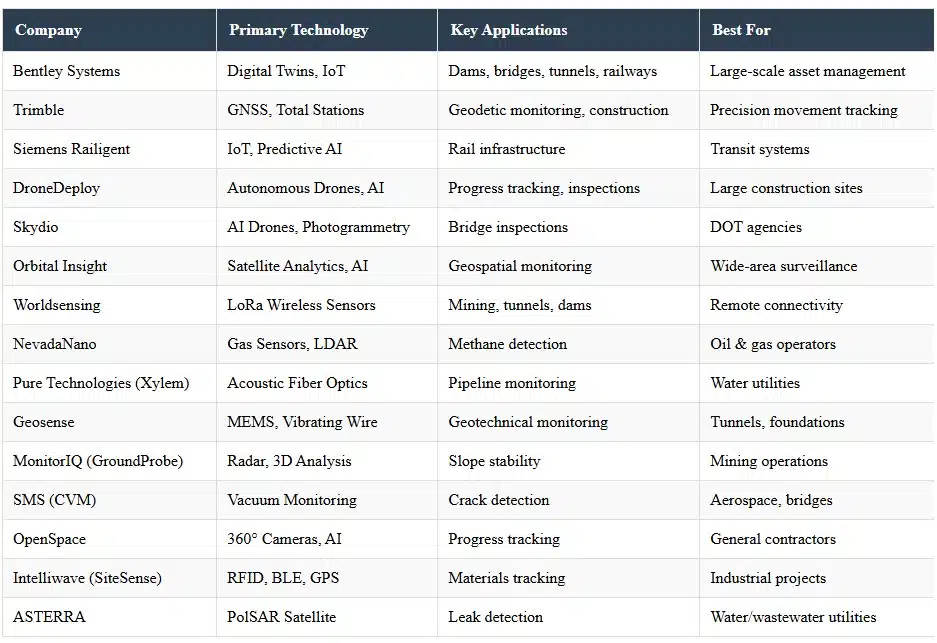

Infrastructure Monitoring Companies Comparison Table

Emerging Trends in Infrastructure Monitoring (USA)

AI-driven structural health monitoring – Machine-learning models are being trained on sensor data to detect anomalies and predict failures. FHWA research has shown that mixed-reality headsets combined with machine learning can identify cracks and damage in bridges during inspections. To develop these critical AI skills for construction professionals, ongoing training is essential.

Predictive maintenance using machine learning – By combining historical inspection records, live sensor feeds and digital twin models, asset owners can forecast when components will reach end-of-life and schedule maintenance before failures occur.

Digital twins for highways and rail networks – Digital twin platforms like Bentley’s iTwin IoT and Siemens’ Railigent create virtual replicas of roads and railways, linking 3D models to sensor data to analyse structural integrity, traffic loads and environmental impacts.

UAV & drone-based remote inspections – The FAA’s DIIG program and BVLOS approvals allow state agencies to deploy drones with cameras, LiDAR and thermal sensors, reducing inspection costs and improving safety. Power utilities such as Florida Power & Light use drones equipped with thermal imaging and LiDAR to inspect poles and equipment according to Inside Unmanned Systems.

Satellite-based change detection – High-resolution optical and radar satellites (e.g., ASTERRA’s PolSAR data) detect ground subsidence, soil moisture changes and infrastructure deformation. These observations cover large areas and supplement ground-based sensors.

Climate-resilience & disaster monitoring – Increasing climate volatility has prompted agencies to monitor infrastructure for floods, wildfires and hurricanes. Sensors and predictive models coupled with FEMA and NOAA data help evaluate structural exposure, inform emergency response and support resilient design.

Buyer’s Guide: Selecting the Right Monitoring Partner

Choosing among infrastructure monitoring companies requires aligning capabilities with project requirements. Consider the following factors:

Budget & total cost of ownership – Evaluate upfront hardware costs, subscription fees, data storage and maintenance. Solutions that reduce on-site labour or prevent failures can offer long-term savings.

Sensor compatibility & scalability – Ensure the platform supports the sensor types (vibration, strain, acoustic, gas, satellite, etc.) required for your assets and can scale across multiple sites.

Data accuracy & reliability – Look for companies with proven track records, third-party certifications (e.g., SOC 2 for cybersecurity) and accurate calibration. Real-time alerts should have low false positives and false negatives.

Integration with BIM, GIS & SCADA – The monitoring system should integrate with existing building information modelling (BIM), geographic information system (GIS) and supervisory control and data acquisition (SCADA) software to avoid data silos. Digital twins can provide a unified interface.

Ease of deployment & maintenance – Wireless sensors and drone solutions reduce installation time. Evaluate whether you need on-site support or if the vendor offers training and managed services.

Cloud security & compliance – Verify that vendors follow industry security standards (e.g., SOC 2, ISO 27001) and can comply with federal data privacy rules. Security is critical when monitoring critical infrastructure.

Challenges in U.S. Infrastructure Monitoring

While monitoring technologies offer immense value, several challenges remain:

Aging infrastructure & funding constraints – The U.S. has a large inventory of older bridges, pipelines and dams that require upgrades. Securing funding for sensors and digital platforms can be difficult when budgets are already stretched.

Skilled workforce shortage – Monitoring systems require trained engineers and data scientists to interpret sensor outputs and maintain equipment. Workforce shortages in the construction and engineering sectors may hinder adoption.

Data privacy & regulatory compliance – Monitoring critical infrastructure raises privacy concerns. Asset owners must comply with federal and state laws, including data sovereignty rules and cybersecurity mandates, which can vary across agencies.

Cybersecurity threats – IoT devices and cloud dashboards are vulnerable to cyberattacks. Without robust encryption, authentication and network segmentation, attackers could manipulate sensor readings or disrupt operations.

Interoperability – Integrating data from disparate sensors, drones and satellite sources into a coherent digital twin remains a technical challenge. Standards and open APIs are needed to avoid vendor lock-in.

Recommended Online Courses for Infrastructure Monitoring Professionals

To build expertise in the technologies driving infrastructure monitoring, consider these courses from leading platforms:

Digital Twins & IoT Courses

- Digital Twins (Coursera – University of Michigan) – Learn how digital twins are applied in manufacturing and infrastructure with real-life case studies from Siemens.

- Mastering Digital Twins (Coursera – EIT Digital) – Understand digital twins fundamentals, benefits, and industrial success stories.

- Internet of Things (IoT) MicroMasters® (edX – Curtin University) – Comprehensive program covering IoT sensors, networks, protocols and solution design.

- IoT Sensors and Devices (edX – CurtinX) – Explore various IoT devices and sensor types for infrastructure monitoring applications.

Construction Management & BIM Courses

- Construction Management Specialization (Coursera – Columbia University) – Master project initiation, scheduling, cost estimating and BIM integration.

- Construction Project Management (Coursera – Columbia University) – Learn fundamentals of project development cycle with BIM applications.

- BIM Fundamentals for Engineers (Coursera – L&T EduTech) – Build foundational BIM skills using Autodesk Revit aligned with ISO 19650 standards.

- Building Smarter: BIM in Practice (Coursera – L&T EduTech) – Comprehensive specialization covering BIM implementation, digital twins and emerging IoT trends.

- BIM Coordination (Coursera – L&T EduTech) – Learn design coordination, clash detection, engineering analysis and visualization techniques.

Drone & UAV Inspection Courses

- Ultimate Guide to Drone Applications – Construction Industry Part 1 (Udemy – HUVIAiR) – Learn drone data collection for the first 5 stages of construction projects.

- Ultimate Guide to Drone Applications – Construction Industry Part 2 (Udemy – HUVIAiR) – Master deviation detection, progress tracking and site inspections using drones.

- Land Surveying with Drones Part 1 (Udemy – HUVIAiR) – Comprehensive guide to flight planning, execution and data processing for drone surveys.

- Professional Guide for Drone Surveying (Udemy) – Best practices for drone deployment, data processing and 3D model generation.

- Fundamentals of Drones & UAV Operations (Udemy – Udaan Aviation) – Business insights on UAV applications in construction and infrastructure inspection.

AI & Data Analytics Courses

- Internet of Things and AI Cloud Specialization (Coursera – UC San Diego) – Learn IoT development, including sensing, actuation, and AWS cloud integration.

- An Introduction to Programming the Internet of Things (IoT) (Coursera – UC Irvine) – Design and create IoT devices using Arduino and Raspberry Pi.

- Digital Technology in Manufacturing (Coursera – L&T EduTech) – Explore Smart Factory concepts, IIoT, ,AI and digital twins for manufacturing and infrastructure.

Conclusion

The 15 infrastructure monitoring companies profiled in this guide represent the cutting edge of structural health monitoring, digital twins, geospatial analytics and autonomous inspection. By harnessing AI, IoT, drones and satellite data, these firms provide real-time insights that help asset owners extend the life of bridges, pipelines, railways and other critical systems, avoid catastrophic failures and optimise maintenance.

Recent collapses and climate challenges underscore the urgency of adopting modern monitoring. With the IIJA and FAA’s DIIG program accelerating investment, the U.S. market is embracing Construction 4.0 technologies faster than other regions. As you explore solutions, consider your specific asset types, data integration needs and regulatory requirements. By partnering with the right company, you can transform passive infrastructure into intelligent systems that safeguard communities and drive sustainable growth.

Frequently Asked Questions

What is infrastructure monitoring and why is it important?

Infrastructure monitoring involves the continuous measurement and analysis of structural and environmental parameters (e.g., strain, vibration, temperature, moisture and gas emissions) to assess the health of bridges, pipelines, dams and other assets. It is essential for preventing failures, extending asset life and ensuring public safety. Digital infrastructure monitoring allows real-time asset monitoring and early detection of issues, reducing maintenance costs.

How do digital twins improve structural health monitoring?

Digital twin monitoring solutions link 3D models with live sensor data to create virtual replicas of infrastructure. They enable engineers to visualise stress, deformation and environmental conditions, simulate scenarios and optimise maintenance. Digital twins can improve capital and operational efficiency by 20–30% according to McKinsey.

What are the benefits of drone-based infrastructure inspections?

Drones equipped with cameras, LiDAR and thermal sensors can inspect structures quickly and safely. Studies show that drone inspections can save up to 75% compared with traditional rope-access methods. They also reduce risk to inspectors and provide high-resolution data for AI infrastructure analytics.

How does satellite-based monitoring detect leaks or subsidence?

Satellite radar, such as ASTERRA’s PolSAR, measures subtle changes in ground moisture and deformation from space. Algorithms identify anomalies indicative of leaks, sinkholes or subsidence across large areas, enabling utilities and agencies to focus ground inspections.

Which companies provide pipeline monitoring solutions?

Pure Technologies (Xylem) offers acoustic fiber optic and SmartBall systems to detect wire breaks and leaks in pipelines. NevadaNano provides gas-sensing platforms for methane leak detection, while ASTERRA’s satellite analytics can locate water leaks.

What is the difference between real-time monitoring and periodic inspections?

Periodic inspections are scheduled at fixed intervals and may miss emerging issues. Real-time monitoring uses sensors, drones or satellites to continuously collect data, providing alerts when thresholds are exceeded. This enables proactive maintenance and reduces the chance of failure.

How can agencies select the right structural health monitoring company?

Agencies should assess their asset types and monitoring goals, then evaluate companies based on technology fit (e.g., sensors vs. drones vs. satellites), data integration capabilities, industry experience, budget and security certifications. Our buyer’s guide above outlines key considerations for choosing an infrastructure monitoring partner.

Are monitoring platforms secure and compliant with regulations?

Leading USA infrastructure monitoring firms obtain certifications like SOC 2 and follow cybersecurity best practices. They employ encryption, authentication and network segmentation to protect data. Agencies should verify compliance with federal and state privacy laws and choose vendors with transparent security policies.

Key Takeaways

- Modern monitoring is critical – Aging infrastructure and climate risks make real-time asset monitoring essential for public safety and resilience.

- Diverse technologies available – Solutions range from digital twin monitoring solutions and GNSS sensors to autonomous drones and satellite analytics.

- Significant cost savings – Drone inspections and predictive maintenance programs can cut inspection costs by up to 75% and extend asset life.

- Data integration is key – Successful programs integrate sensor data with BIM, GIS and asset management systems to deliver actionable insights.

- Choose wisely – Evaluate vendors based on technical fit, industry experience, security compliance and support services.