Last Updated on December 18, 2024 by Admin

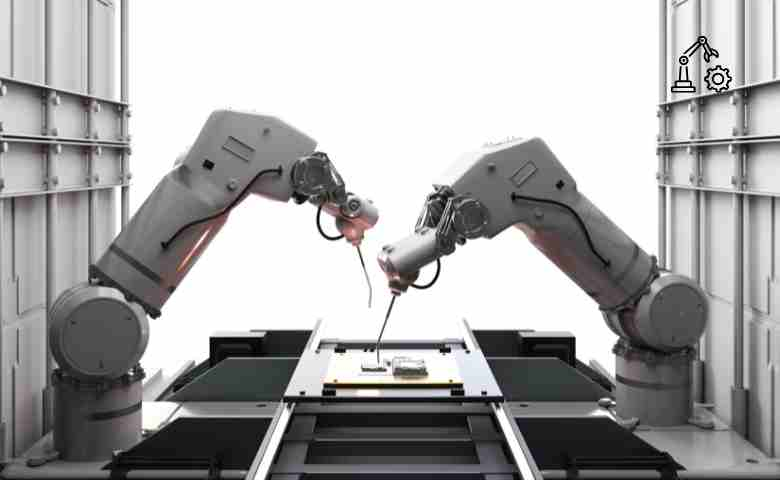

Industrial automation systems have changed the operations of all industries and are widely accepted worldwide. This advancement has brought a positive change in several ways and has improved the manufacturing line and output.

ConstructionCareerHub App is LIVE — built ONLY for construction careers. Don’t apply with a weak resume.

Get ATS-ready Resume Lab + Interview Copilot + Campus Placement Prep (resume screening, skill gaps, interview readiness) — in minutes & Other advanced features.

Explore Smarter Construction Career Tools →Quick check. Big impact. Start now.

Table of Contents

Key Components of Industrial Automation

Industrial automation systems can thus comprise one or many components that are normally connected to achieve specific results. These components include:

Sensors:

Sensors form the basis of any industrial automation system since they deliver vital information involved in automating the manufacturing process. There are numerous types of sensors, such as temperature, pressure, optical, and many more. They assist machines in identifying alterations in the production process environment so that dynamic data collection, analysis, and decision-making can be conducted effectively.

Actuators:

An actuator is a device that transforms energy into movement and enables automatic systems to perform tasks in a regulated way. It can be mechanical, hydraulic, or pneumatic and is involved in moving, controlling, or manipulating material, components, and finished products on a production line.

Controllers:

A controller in an industrial automation system is a computing element that acquires data from sensors, performs necessary calculations on the data, and produces control signals for actuators’ actions. Controllers can be Programmable Logic Controllers (PLCs) or computer-based controllers that control and process data, make decisions, and transmit information in the system.

Human-machine interface (HMI):

The automated system’s graphical terminal is where the operators communicate with the system and get an observational view of how it operates. HMIs can show actual data and the control system’s settings and provide an easy mode of operation for adjusting, identifying, and observing the running condition.

Communication networks:

Effective communication protocols are important in industrial automation because the system is composed of sensors, controllers, actuators, and HMIs, all of which must communicate effectively.

Advantages of using Automation in Industries

The adoption of industrial automation offers a multitude of benefits for businesses, including:

Increased productivity:

They can run 24 hours a day without being closed down, which increases manufacturing efficiency. This way, people will make fewer errors, everything will be processed faster, and businesses will be able to produce more and satisfy the market’s needs.

Improved quality:

Industries can demonstrate increased control, quality, and reliability through industrial automation. This implies that when using automated techniques, there is likely to be less waste and scrapes and, consequently, less required for quality control checks and correction.

Enhanced safety:

Automation can perform some operations that are either dangerous or difficult for people to do, such as working with toxic substances, being exposed to high heat or cold, or moving large objects. When operations are made less dependent on human beings, the likelihood of workers being hurt on duty is lessened, and the working space becomes less risky.

Reduced costs:

Another benefit of industrial automation is that it can significantly reduce the price that companies pay for work done by minimizing labor expenses and wastage while increasing efficiency.

Increased flexibility:

The typified automated systems can be easily changed to fit new requirements in the materials’ production, allowing the shortest time to address the changing market demands. Such flexibility is especially beneficial in low-production, small-bath, high-variation manufacturing situations, where variation and customization dominate.

Improved data collection and analysis:

Industrial automation systems can, therefore, gather a lot of information that helps enhance production processes. Through this data, companies can discover what needs to be changed, where to improve an organization’s processes, and where to make the right decisions to achieve organizational efficiency.

Applications of Industrial Automation

Industrial automation is being integrated into many industries, changing how organizations function as well as the competitiveness of a firm. Some of the key applications of Industrial automation services include:

Manufacturing:

Factory automation is a welcome idea in manufacturing since it allows for greater production of quality goods while meeting customer specifications. Many industries have manufacturing procedures, and if these procedures are automated to include welding, painting, and assembly, the company will be able to cut costs and maximize productivity.

Oil and gas:

The oil and gas industry has been characterized by increased demand for automation systems to implement and supervise elaborate processes, including drilling, extraction, and refining. According to the information, by applying the automated system, it is possible to enhance safety, minimize adverse environmental effects, and maximize production rate.

Power generation:

Automated control is essential while measuring and regulating power plants within the power generation segment to obtain reliable electricity production. Smart technologies can enhance the workings of power generation facilities- turbines, boilers, generators, etc.- enabling a company to save on costs.

Transportation:

Technology is now a major factor in transporting systems that cover self-driven vehicles, traffic control, and automation of material handling systems. These methods can accrue benefits such as enhanced transport safety, traffic reduction, and elevated transport productivity.

Food and beverage:

Industrial automation has taken root dramatically in the food and beverage industry to enhance food safety and quality. These robust systems are used in packaging, labeling, and distribution to ascertain that the goods are of the right quality and delivered to clients when they are required.

Pharmaceuticals:

Automating the pharmaceutical industry is necessary to ensure the high quality of its products and minimize possible errors. Industrial automation expands from dispensing systems to sophisticated functions such as robotic drug packaging to produce quality, safe medications with a reduced risk of human interference.

Challenges and Considerations in Industrial Automation

While industrial automation offers numerous benefits, there are also challenges and considerations that businesses need to address:

Cost of implementation:

Numerous costs are associated with industrial automation, and its application is also a major capital investment in terms of hardware, software, and services. Implementing such a practice might initially seem costly; however, over the long run, organizations often identify potential savings to offset such costs.

Complexity of integration:

Various components and systems for industrial automation are available, but implementing them may involve protracted integration of both hardware and software.

Cybersecurity risks:

Industrial automation systems are originally rather interconnected and complex, and this can be dangerous in terms of cybersecurity threats. Modern businesses need firewalls, intrusion detection systems, and secure forms of communication when conducting their operations.

Workforce displacement:

Industrial automation technologies create unemployment since mechanical production replaces human effort in the workforce. One of the disadvantages of business automation is that it leads to job loss; hence, business owners should be willing to support and train employees who may lose their jobs due to the new change in business operations.

Ethical considerations:

Many issues need to be addressed in connection with the use of industrial automation; these include its effect on the creation of employment, the increase in inequality, and the position of people as employees in the new industrial age.

Conclusion

Industrial automation is transforming industries across the globe, empowering businesses to optimize their operations, enhance productivity, and unlock unprecedented levels of efficiency. Automation is reinventing the manufacturing industry by combining intelligent machines and cutting-edge software to drive innovation and new opportunities for growth.

Related Posts:

- How Construction Equipment Can Be Modified and Improved to Easier Works

- The Evolution of Construction 4.0: A Comprehensive Guide

- Robots on the Rise: Automation in Construction

- The Role of Artificial Intelligence in Revolutionizing Online Experiences