Last Updated on December 4, 2025 by Admin

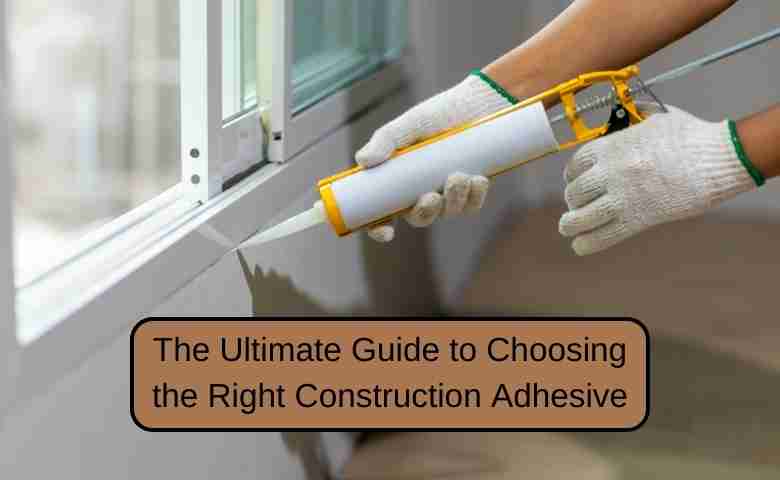

When embarking on any construction project, whether a simple DIY jo b or a large-scale commercial build, choosing the right construction adhesive is one of the most crucial elements to ensure structural integrity and long-term durability. These adhesives are the invisible forces that bond materials together, providing strength and stability to your construction. Selecting the appropriate adhesive can make or break the success of your project. In this guide, we’ll walk you through the different types of construction adhesives, how to choose the best one based on material and application, and the pros and cons of each type.

ConstructionCareerHub App is LIVE — built ONLY for construction careers. Don’t apply with a weak resume.

Get ATS-ready Resume Lab + Interview Copilot + Campus Placement Prep (resume screening, skill gaps, interview readiness) — in minutes & Other advanced features.

Explore Smarter Construction Career Tools →Quick check. Big impact. Start now.

Table of Contents

Understanding Construction Adhesives: What Are They?

Construction adhesives are specially formulated bonding agents that adhere to various building materials. They offer solid and long-lasting bonds resistant to environmental stresses, including temperature fluctuations, moisture, and vibration. Due to their versatility and ability to bond materials that mechanical fasteners cannot, they are widely used in everything from basic home repairs to large infrastructure projects.

The suitable construction adhesive can replace nails, screws, and other traditional fasteners in specific applications, improving the aesthetics of the finished product while offering greater flexibility in assembly.

Types of Construction Adhesives

Different types of adhesives are suited to different applications. To help you choose the best option, here is an overview of the main types of construction adhesives:

1. Polyurethane-Based Adhesives

Polyurethane adhesives are among the most versatile adhesives in construction. Known for their excellent bonding properties across a wide range of materials, they provide a strong, waterproof bond and can be used both indoors and outdoors.

Best For:

- Wood

- Metal

- Stone

- Concrete

- Glass

- Plastic

Pros:

- Extremely strong bond.

- Waterproof, making it ideal for outdoor applications.

- Works well in both high and low temperatures.

- Expands slightly as it cures, helping to fill gaps between materials.

Cons:

- Can be more expensive than other types.

- Takes longer to cure, requiring patience during projects.

- Cleanup can be messy due to its expanding nature.

2. Epoxy Adhesives

Epoxy adhesives are known for their superior strength and durability. Made from a combination of resin and hardener, epoxy adhesives create an exceptionally strong chemical bond that can withstand heavy loads. They are used in high-performance applications where other adhesives would fail.

Best For:

- Metal

- Concrete

- Glass

- Stone

- Some plastics

Pros:

- High strength, ideal for heavy-duty applications.

- Excellent resistance to chemicals, heat, and moisture.

- Bonds well to non-porous materials like metal and glass.

Cons:

- Requires precise mixing of the resin and hardener for optimal results.

- Limited working time before the adhesive sets.

- Can be brittle once cured, making it unsuitable for flexible materials.

3. Silicone Adhesives

Silicone adhesives are highly flexible and resistant to extreme temperatures, moisture, and chemicals. They are widely used in applications where the bond will be exposed to environmental elements or require a degree of flexibility.

Best For:

- Glass

- Metal

- Ceramic

- Plastic

- Rubber

Pros:

- Highly resistant to moisture, making it ideal for bathrooms and kitchens.

- Flexible, making it suitable for materials that expand or contract.

- Excellent for sealing applications.

Cons:

- Not suitable for weight-bearing applications.

- Can be more expensive than other adhesives.

- Long cure times.

4. Latex-Based Adhesives

Latex-based adhesives are water-based adhesives that are easy to work with, non-toxic, and clean. These adhesives are typically used for lighter materials and in applications where flexibility is needed.

Best For:

- Wood

- Drywall

- Carpet

- Foam

- Tile

Pros:

- Easy to clean up with water before it cures.

- Flexible, making it great for materials that expand and contract.

- Dries quickly and is non-toxic.

Cons:

- Not as strong as solvent-based adhesives.

- Not suitable for outdoor applications or areas exposed to moisture.

- Can degrade over time when exposed to extreme conditions.

5. Acrylic Adhesives

Acrylic adhesives are strong and versatile, offering excellent bonding properties for various materials. They cure quickly and are resistant to water and UV light, making them a popular choice for both indoor and outdoor projects.

Best For:

- Metal

- Glass

- Plastic

- Wood

Pros:

- Fast curing time.

- Strong bond that is resistant to moisture and UV light.

- Versatile, working on a range of materials.

Cons:

- Can be less flexible than other adhesive types.

- Strong fumes during application, requiring ventilation.

- Higher cost than some alternatives.

6. Polyvinyl Acetate (PVA) Adhesives

PVA adhesives, commonly known as wood glue, are widely used in woodworking projects. These water-based adhesives are known for their ease of use and strong bond with wood surfaces.

Best For:

- Wood

- Paper

- Some fabrics

Pros:

- Easy to clean up with water.

- Dries clear, leaving no visible residue.

- Non-toxic and safe for indoor use.

Cons:

- Not waterproof, limiting outdoor applications.

- Not ideal for non-porous materials like metal or plastic.

- Can take a long time to cure fully.

7. Contact Cement

Contact cement is a highly versatile adhesive that forms an instant bond once two surfaces are pressed together. It is ideal for bonding large surface areas where traditional adhesives might not work.

Best For:

- Laminate

- Wood veneer

- Leather

- Plastic

- Rubber

Pros:

- Instant bond once applied to both surfaces.

- Very strong adhesive, especially for large surfaces.

- Suitable for bonding dissimilar materials.

Cons:

- Little to no room for error—once surfaces are pressed together, adjustments are difficult.

- Releases strong fumes during application.

- Can be difficult to clean up.

Related Posts:

- Choosing the Right Materials for Durable Commercial Buildings

- Top 100 Construction Materials Every Civil Engineer Must Understand

- Recycled Materials for Building Construction: A Sustainable Approach for the Future

- The Role of High-Performance Materials in Extreme Industrial Environments

How to Choose the Right Construction Adhesive Based on Material

Choosing the right construction adhesive involves understanding the materials you are working with and selecting an adhesive that is compatible with those materials. Below is a breakdown of common materials and the adhesives best suited for them:

1. Wood

For wood, the best adhesives are typically PVA adhesives (wood glue), polyurethane adhesives, and epoxies for heavy-duty applications. PVA is easy to use and ideal for woodworking projects, while polyurethane provides added water resistance for outdoor applications.

2. Metal

For bonding metal, epoxy adhesives and acrylic adhesives are the best options. Epoxy provides a powerful bond and is resistant to heat and chemicals, making it perfect for industrial applications. Acrylic adhesives offer quicker drying times and versatility, especially for lighter metal projects.

3. Concrete

When working with concrete, you need an adhesive that offers strong bonding and moisture resistance. Polyurethane adhesives are ideal for concrete, as they provide a strong, waterproof bond. Epoxy adhesives are also suitable for high-strength applications where durability is key.

4. Glass

For glass, silicone adhesives are the best choice. They provide a flexible, waterproof bond and can withstand temperature fluctuations. Acrylic adhesives can also be used for glass in outdoor applications, as they are resistant to UV light.

5. Plastic

For bonding plastic, epoxy adhesives, acrylic adhesives, and polyurethane adhesives work well. Some plastics can be difficult to bond, so be sure to check the adhesive’s compatibility with the specific type of plastic you are using.

6. Tile and Ceramic

Latex-based adhesives are commonly used for tile applications due to their flexibility and ease of use. For heavier tiles or outdoor applications, epoxy adhesives are recommended for their strength and water resistance.

7. Rubber

For rubber, contact cement and silicone adhesives are the best options. Contact cement provides an instant bond, while silicone adhesives offer flexibility and resistance to moisture and temperature fluctuations.

Related Posts:

- The Latest Sustainable Building Materials and Techniques used in the construction industry

- 150 Interview Questions and Answers on Building Materials and Techniques

- How To Select Stairway Materials For A Commercial Building

- The Ultimate Guide to Civil Engineering Materials: What Every Engineer Should Know

Factors to Consider When Choosing a Construction Adhesive

While material compatibility is a primary factor in choosing the right adhesive, there are several other considerations to keep in mind:

1. Bond Strength

The strength of the adhesive you choose should match the demands of your project. You’ll want a strong adhesive like epoxy or polyurethane for heavy-duty applications or materials that will bear weight.

2. Curing Time

Curing time varies significantly between adhesive types. Epoxy adhesives can take several hours to fully cure, while acrylic adhesives and contact cement bond almost instantly. Consider how much time you have for the adhesive to set.

3. Environmental Exposure

Will the bonded materials be exposed to moisture, heat, or chemicals? For outdoor projects or areas exposed to harsh environments, choose an adhesive resistant to these elements, such as silicone or polyurethane.

4. Flexibility

Certain materials like wood or rubber expand and contract with temperature and humidity changes. In these cases, you’ll need flexible adhesive, such as silicone or latex-based adhesives.

5. Ease of Application

Some adhesives, like PVA and latex-based adhesives, are very user-friendly and easy to clean up, making them ideal for DIY projects. Epoxy and polyurethane, on the other hand, require more care during application.

Final Reflections

Selecting the right construction adhesive for your project can seem overwhelming. Still, by considering the materials you’re working with, the environmental conditions, and the specific demands of your project, you can make an informed choice. Whether you need the strength of an epoxy, the flexibility of silicone, or the simplicity of PVA, a construction adhesive is designed to meet your needs.

By understanding the properties of each adhesive type, you’ll be able to achieve the best results, ensuring that your project is structurally sound and built to last.

Related Posts:

- The Ultimate Guide to the Different Types of Garage Floor Coatings

- A Contractor’s Guide to Construction Project Bonding in 2024

- The Types of Flooring Suitable in Industrial Areas

- The Ultimate Guide to Metal Buildings: Everything You Need to Know