Last Updated on November 3, 2025 by Admin

In today’s construction landscape, Mechanical, Electrical, and Plumbing (MEP) systems represent 30-40% of total building costs and are the backbone of modern infrastructure. Yet, coordinating these complex, interdependent systems remains one of the most challenging aspects of construction project delivery. With building codes constantly evolving and projects facing tight schedules, understanding and solving MEP coordination challenges has never been more critical.

This comprehensive guide explores the common MEP coordination challenges facing construction professionals in 2025 and provides actionable solutions backed by industry data and real-world case studies.

Table of Contents

What is the MEP Coordination Process?

The MEP coordination process involves integrating mechanical, electrical, and plumbing systems within a building to ensure seamless operation, efficiency, and occupant comfort. This integration enhances the overall functionality of the building, making it more efficient and comfortable for its occupants.

MEP engineering encompasses the design, installation, and maintenance of critical building systems that make structures functional and safe. The coordination process typically includes:

- Design Integration – Combining architectural, structural, and MEP models

- Clash Detection – Identifying spatial conflicts between systems

- Resolution Planning – Developing strategies to resolve conflicts

- Documentation – Creating coordinated MEP coordination drawings

- Field Coordination – Ensuring on-site installation matches design intent

- Commissioning – Verifying system performance

The global construction industry, valued at $7.28 trillion in 2025, increasingly relies on sophisticated coordination processes to deliver projects on time and within budget. Learn more about MEP career opportunities in this growing field.

Key MEP Coordination Challenges

1. Complex System Interdependencies

Integrating mechanical, electrical, and plumbing systems in construction projects is inherently complex, with each system having its own requirements. These systems must work harmoniously within limited ceiling spaces, creating coordination nightmares.

Impact:

- Poor coordination can lead to clashes between systems, delays in construction, and increased costs

- Rework can consume 5–15% of total project costs

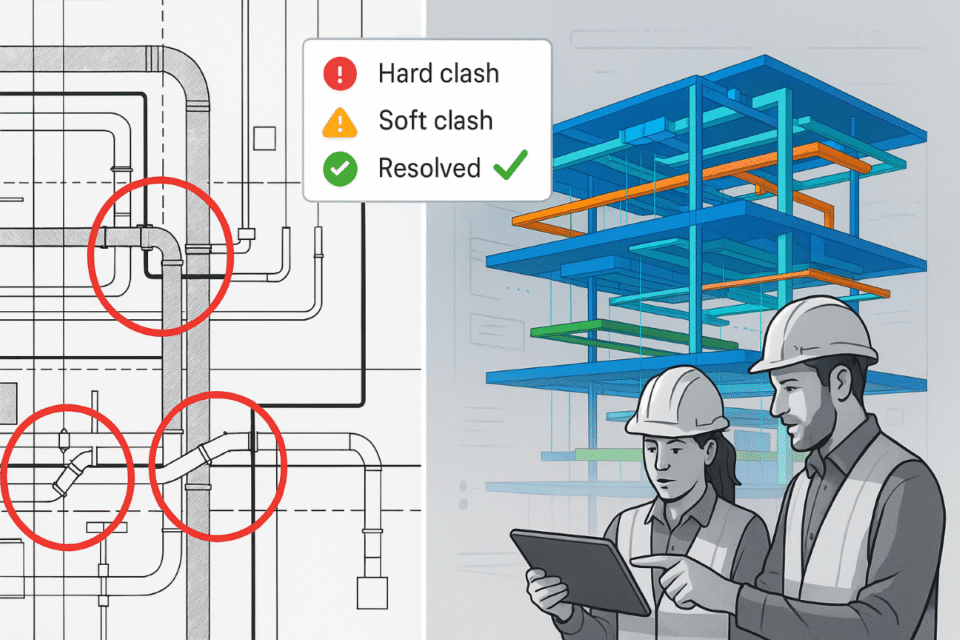

2. Spatial Conflicts and Clash Management

Spatial conflicts, or clashes, occur when MEP systems intersect with structural elements, architectural features, or other MEP components. These include:

- Hard Clashes: Physical conflicts where components occupy the same space (e.g., ductwork through structural beams)

- Soft Clashes: Insufficient clearances for maintenance, access, or safety requirements

- Workflow Clashes: Timing conflicts in construction sequencing

The mechanical, electrical, and plumbing systems need to interact without overlapping, and attempting to plan these layouts without proper coordination may result in a final design that’s replete with clashes and conflicts.

3. Evolving Building Codes and Compliance

One of the significant challenges in MEP coordination is dealing with constantly evolving building codes. For multi-year projects, owners may request compliance with future code cycles before they’re officially released, creating uncertainty in design requirements.

Challenge: If a project starts in 2024, owners might demand compliance with 2025 code cycles that aren’t yet finalized.

4. Decentralized Design Responsibility

The decentralized design responsibility in traditional coordination systems means that different teams may be responsible for designing different parts of the building systems, leading to:

- Communication breakdowns between disciplines

- Design errors and misalignments

- Costly rework during construction

- Extended project timelines

5. Inefficient Pre-Construction Reviews

The traditional coordination system requires multiple meetings and reviews with project teams before construction begins, which can be time-consuming and inefficient. The use of 2D drawings often results in incomplete or inaccurate representations.

6. Technology Adoption Barriers

A significant barrier is the fear of job security among field workers and the perceived complexity of these tools. Despite the proven benefits of Building Information Modeling (BIM), many firms struggle with implementation.

7. Space Constraints in Ceiling Plenum

The interconnectedness of MEP pipes and ducts spanning the building’s entirety poses a challenge for engineers to fit these elements within limited ceiling heights, historically resulting in rework and increased costs.

8. What are the key challenges in coordinating carpentry and MEP works?

Coordinating carpentry with MEP systems presents unique challenges:

- Structural penetrations for MEP routing through wooden framing

- Load-bearing considerations when running services through structural elements

- Fire-stopping requirements at penetrations

- Acoustic isolation between MEP equipment and occupied spaces

- Accessibility for future maintenance without compromising carpentry work

Solutions to MEP Coordination Problems

1. Implement Building Information Modeling (BIM)

Building Information Modeling is changing the construction industry, particularly in the MEP sector, allowing for creating detailed 3D models that integrate mechanical, electrical, and plumbing systems.

Proven Results:

- For a $200,000 VDC labor effort, one project achieved $2.22 million in rework savings and an additional $542,000 in schedule savings, resulting in net savings of $2.55 million, or an ROI of 10x

- Clash detection was found to reduce design errors by over 70%, save an estimated 30% of project time

BIM Benefits:

- BIM facilitates better coordination, reduces clashes, and improves overall project efficiency by visualizing potential issues before construction begins

- Most BIM software platforms feature rule-based routing capabilities, notifying engineers of any code violations in pipe or duct placement

Explore more about BIM career opportunities in the construction industry.

2. Advanced Clash Detection Software

Leverage specialized tools like Autodesk Navisworks and Revit for comprehensive clash detection:

Latest Technology: A Modified Extreme Gradient Boosting (MXGBoost) algorithm achieved a Mean Absolute Error of 0.057, a Mean Squared Error of 0.0034, and an Area Under the Receiver Operating Characteristic Curve of 0.972 in automated clash detection.

Clash Detection ROI:

- If a mid-sized project runs $30M and rework averages 10% of costs, that’s $3M at stake. Reducing even a fraction through early clash resolution represents meaningful savings

3. Prefabrication and Modular Construction

Prefabrication involves building parts of MEP systems in a factory, with workers transporting these parts to the construction site for assembly. This approach:

- Reduces on-site conflicts

- Improves quality control

- Shortens installation time

- Minimizes field coordination issues

Learn about starting a MEP services business focused on prefabrication.

4. Establish Clear Communication Protocols

The general contractor should act as the anchor of all communications on the worksite when it comes to MEP coordination.

Best Practices:

- Hold structured MEP coordination meeting agenda sessions

- Use centralized collaboration platforms

- Establish clear decision-making hierarchies

- Document all coordination decisions

5. Early Stakeholder Involvement

How do you coordinate with architects, structural engineers, and other stakeholders to ensure that MEP systems are integrated effectively?

The key is early and continuous engagement:

- Initial Kick-off Meetings: During the first pre-construction meeting, establish a solid agenda and assign timelines and deadlines for each system

- Integrated Design Approach: Bring all disciplines together from project inception rather than sequential design phases

- Regular Coordination Sessions: Weekly or bi-weekly meetings to review progress and resolve conflicts

- Shared Digital Platforms: Establish a platform where all trades can make updates, ensuring everyone is looking at a live model

- Collaborative Decision-Making: Use clash responsibility matrices to assign resolution roles based on system hierarchy

6. Implement Virtual Design and Construction (VDC)

Virtual Design and Construction has revolutionized MEP design through precise visualization, improved cooperation, and early identification of clashes. VDC enables:

- Intricate virtual model coordination

- Conflict spotting before construction

- Layout refinement in digital environment

- Precise quantity evaluations and cost estimations

7. Develop MEP Coordination Rules and Standards

Establish project-specific coordination rules covering:

- Priority hierarchies (e.g., structure > MEP > architecture)

- Minimum clearance requirements

- Routing preferences (overhead vs. underground)

- Access and maintenance requirements

- Code compliance checkpoints

8. Artificial Intelligence and Machine Learning

Despite resistance, there are many potential benefits of integrating technology into MEP coordination. BIM systems can greatly benefit from AI-driven clash detection.

AI Advantages:

- Automated clash detection and prioritization

- Predictive analytics for potential conflicts

- Expedited submittal processes

- Pattern recognition in recurring issues

The Role of a MEP Coordinator

What is the role of a MEP coordinator?

An MEP coordinator serves as the linchpin of successful project delivery, responsible for:

Primary Responsibilities:

- Technical Coordination

- Review and integrate MEP models from different disciplines

- Conduct clash detection and resolution

- Ensure compliance with building codes and standards

- Coordinate MEP coordination drawings production

- Communication Management

- Facilitate coordination meetings between stakeholders

- Maintain coordination logs and issue tracking

- Distribute updated models and drawings

- Escalate critical conflicts to project management

- Quality Assurance

- Verify design intent is maintained

- Ensure constructability of coordinated systems

- Review shop drawings and submittals

- Validate field installations against coordinated models

- Documentation

- Maintain comprehensive coordination records

- Prepare clash reports and resolution matrices

- Update construction sequence documentation

- Create as-built coordination models

Required Skills and Qualifications:

MEP coordinators typically need:

- Bachelor’s degree in mechanical, electrical, or related engineering field

- Proficiency in BIM software (Revit, Navisworks, AutoCAD MEP)

- Strong understanding of all MEP systems

- Excellent communication and problem-solving skills

- Knowledge of construction means and methods

MEP Coordinator Salary:

In India: ₹3.5 Lakhs to ₹10.0 Lakhs annually, with an average of ₹4.5 Lakhs

Globally: Ranges from $35,000-$60,000 in emerging markets to $84,000-$150,000+ in developed economies, with specialized coordinators commanding premium salaries for BIM expertise.

MEP Coordination Checklist

Pre-Design Phase

- Define project BIM execution plan (BEP)

- Establish coordination standards and protocols

- Identify key stakeholders and communication channels

- Set up Common Data Environment (CDE)

- Define Level of Development (LOD) requirements

Design Phase

- Conduct initial discipline model reviews

- Perform preliminary clash detection

- Verify code compliance for all systems

- Coordinate with architectural and structural models

- Review spatial requirements and clearances

- Validate system capacities and sizing

- Prepare coordinated MEP coordination drawings PDF

Pre-Construction Phase

- Finalize coordinated 3D model

- Complete comprehensive clash detection

- Resolve all critical and high-priority clashes

- Create MEP construction sequence PDF

- Prepare fabrication models for prefab elements

- Generate shop drawing requirements

- Conduct constructability reviews

Construction Phase

- Establish field coordination procedures

- Track RFIs and field changes

- Update models based on field conditions

- Coordinate installation sequences

- Verify as-built conditions

- Support commissioning activities

- Document lessons learned

Best Practices and MEP Coordination Rules

1. Vertical System Priority

Establish clear hierarchies:

- Structure (non-negotiable)

- Fire protection systems (life safety)

- Large mechanical systems (difficult to reroute)

- Electrical systems (flexible routing)

- Plumbing (most flexible)

2. Coordination Zones

The project management team filtered approximately 932 of 2000 total clashes to review and assign cost magnitude only to higher-priority items (Critical, High, and Medium), grouped by work zone.

Divide projects into manageable coordination zones:

- Mechanical rooms and equipment spaces

- Vertical shafts and risers

- Horizontal distribution corridors

- Congested ceiling areas

- Exterior wall penetrations

3. Clearance Standards

Maintain minimum clearances:

- HVAC ducts: 6″ from structure, 3″ between parallel runs

- Electrical conduit: 12″ from water lines, 2″ from other conduits

- Plumbing pipes: 6″ from electrical panels

- Equipment access: Per manufacturer specifications + 20%

4. Documentation Requirements

- Maintain version control for all models

- Document all coordination decisions

- Create detailed clash reports with resolutions

- Preserve audit trail for code compliance

- Prepare comprehensive as-built documentation

5. Technology Best Practices

Implementing a collaborative workflow where all stakeholders work within a shared BIM environment promotes better communication and coordination.

- Use federated models for coordination

- Automate clash detection runs (weekly minimum)

- Leverage cloud-based collaboration tools

- Implement QA/QC checkpoints

- Integrate AI-driven clash prioritization

6. Sustainable MEP Coordination

MEP plans for 2024 are well mapped out, with sustainability being the pivotal element in reducing the project’s environmental footprint.

Consider:

- Energy-efficient system layouts

- Optimal equipment locations for performance

- Renewable energy integration paths

- Water conservation system coordination

- Material waste reduction through prefabrication

Industry Resources and Tools

Software Platforms:

- Autodesk Revit MEP – Primary modeling platform

- Navisworks – Clash detection and coordination

- BIM 360 – Cloud collaboration

- Procore – Construction management

Professional Organizations:

- ASHRAE – HVAC standards and guidelines

- NFPA – Fire protection codes

- NEC – Electrical code requirements

- ASPE – Plumbing engineering standards

Additional Learning:

Explore top MEP consultants in India for professional partnerships and civil engineering companies in the US that specialize in MEP coordination.

Conclusion

MEP coordination challenges, while complex, are increasingly manageable through modern technology, established best practices, and professional coordination processes. The ROI from clash detection can be eye-opening, with proactive BIM coordination preventing costly issues and delivering real savings—over $2.5 million in cost and time savings on a single project.

Key takeaways for successful MEP coordination:

- Invest in BIM Technology: The 10x ROI demonstrated in real projects justifies the initial investment

- Start Early: Coordination must begin in pre-design, not during construction

- Communicate Constantly: Use shared platforms and regular meetings

- Establish Clear Rules: Define priorities, clearances, and decision-making processes

- Hire Skilled Coordinators: Professional MEP coordinators are worth their weight in gold

- Document Everything: Comprehensive records protect all stakeholders

- Embrace Prefabrication: Off-site assembly reduces field conflicts

- Stay Current: Building codes and technology constantly evolve

As the construction industry continues advancing toward digital transformation, mastering MEP coordination becomes not just a competitive advantage but a necessity for successful project delivery.

Whether you’re an MEP engineer, project manager, or contractor, understanding and implementing these coordination strategies will position you for success in an increasingly complex construction landscape.

Ready to advance your MEP career? Explore mechanical engineering job opportunities and take practice tests for MEP engineer positions to assess your skills.

Need expert consultation? Connect with leading MEP consultants to tackle your coordination challenges.

This article was last updated in November 2025 to reflect the latest industry practices, technology advancements, and real-world case studies in MEP coordination.

Frequently Asked Questions (FAQs)

Coordinating carpentry with MEP systems requires careful attention to:

Structural penetrations: Planning holes and chases through wooden framing for MEP routing

Load transfer: Ensuring MEP equipment doesn’t compromise structural integrity

Fire-stopping: Maintaining fire ratings at all penetrations

Acoustic isolation: Preventing sound transmission from MEP equipment

Maintenance access: Ensuring removable carpentry elements for future MEP service

Sequencing: Coordinating rough-in timing with framing completion

The key is early coordination meetings between carpenters and MEP trades, detailed shop drawings showing all penetrations, and clear field verification procedures.

The MEP coordination process involves:

Model Integration: Combining architectural, structural, and MEP discipline models

Clash Detection: Running automated checks to identify conflicts

Priority Assessment: Categorizing clashes by severity and impact

Resolution Development: Engineering solutions for identified conflicts

Stakeholder Review: Presenting solutions to affected parties

Documentation: Recording decisions and updating models

Field Coordination: Ensuring installation matches coordinated design

Verification: Confirming as-built conditions match coordination

This iterative process continues throughout design and construction phases, with regular coordination cycles (typically weekly or bi-weekly).

An MEP coordinator manages the technical coordination of all building systems, serving as the central point of contact between disciplines. Key responsibilities include:

Conducting clash detection and facilitating resolution

Organizing and leading coordination meetings

Maintaining coordination documentation and models

Ensuring code compliance across all systems

Coordinating with architects and structural engineers

Managing RFIs and design changes

Supporting field installation and commissioning

They require strong technical knowledge, BIM proficiency, and excellent communication skills to balance competing priorities and stakeholder interests.

Effective coordination requires:

Early Engagement: Involve all stakeholders from project inception, not after architectural design is complete.

Regular Communication: Establish a platform where all trades can make updates, ensuring everyone is looking at a live model. This constant communication helps identify and address issues before they escalate.

Clear Protocols: Define decision-making hierarchies, coordination standards, and communication channels upfront.

Integrated Modeling: Use federated BIM models where all disciplines work in a shared digital environment.

Structured Meetings: Follow a consistent MEP coordination meeting agenda covering:

Model updates since last meeting

New clashes identified

Resolution status of previous issues

Upcoming milestones and deadlines

Code changes or design modifications

Documentation: Maintain comprehensive records of all coordination decisions, ensuring accountability and traceability.

Field Integration: Bridge design coordination with construction reality through regular site visits and field verification.