Last Updated on July 7, 2025 by Admin

The construction industry stands at a critical juncture. With global concrete production exceeding 4 billion tons annually and traditional formwork systems contributing to nearly 40% of construction expenses while generating massive waste streams, the sector desperately needs innovative solutions. Enter 3D printed bioplastic formwork—a revolutionary technology that promises to slash construction waste by an unprecedented 70% while transforming how we approach concrete casting and structural building.

ConstructionCareerHub App is LIVE — built ONLY for construction careers. Don’t apply with a weak resume.

Get ATS-ready Resume Lab + Interview Copilot + Campus Placement Prep (resume screening, skill gaps, interview readiness) — in minutes & Other advanced features.

Explore Smarter Construction Career Tools →Quick check. Big impact. Start now.

For construction project managers, formwork contractors, and engineers who’ve watched countless wooden forms end up in landfills after single use, this technology represents more than just an environmental win. It’s a paradigm shift that addresses three critical industry challenges simultaneously: escalating material costs, labor shortages, and mounting regulatory pressure for sustainable practices.

Table of Contents

The Current State of Construction Waste: A Crisis Demanding Innovation

Understanding the Magnitude of the Problem

The construction industry generates approximately 1.3 billion tons of waste annually worldwide, with traditional formwork systems playing a significant role in this environmental burden. Current timber-based formwork, despite its widespread use, presents multiple sustainability challenges that have plagued the industry for decades.

Key Statistics Revealing the Crisis:

- Formwork accounts for 40% of concrete construction expenses

- Traditional wooden forms are typically discarded after 3-5 uses

- Construction waste contributes to 30% of total global waste generation

- Only 9% of construction plastics are effectively recycled

- Formwork-related waste increases project costs by 15-25%

The Hidden Costs of Traditional Formwork

Beyond the obvious environmental impact, traditional formwork systems impose substantial hidden costs on construction projects. These include:

Labor Intensive Operations: Skilled carpenters require 2-3 days to construct complex formwork systems that 3D printing can produce in hours. With skilled labor shortages affecting 80% of construction firms globally, this time dependency creates project delays and cost overruns.

Material Waste Multiplication: Each traditional formwork cycle generates secondary waste through cutting, modification, and disposal. Research indicates that timber formwork projects produce 20-30% more waste than initially calculated due to these secondary processes.

Transportation and Storage Burdens: Bulky wooden forms require significant transportation resources and on-site storage space, adding logistical complexity and costs to projects.

Introducing 3D Printed Bioplastic Formwork: The Game-Changing Solution

What Makes This Technology Revolutionary

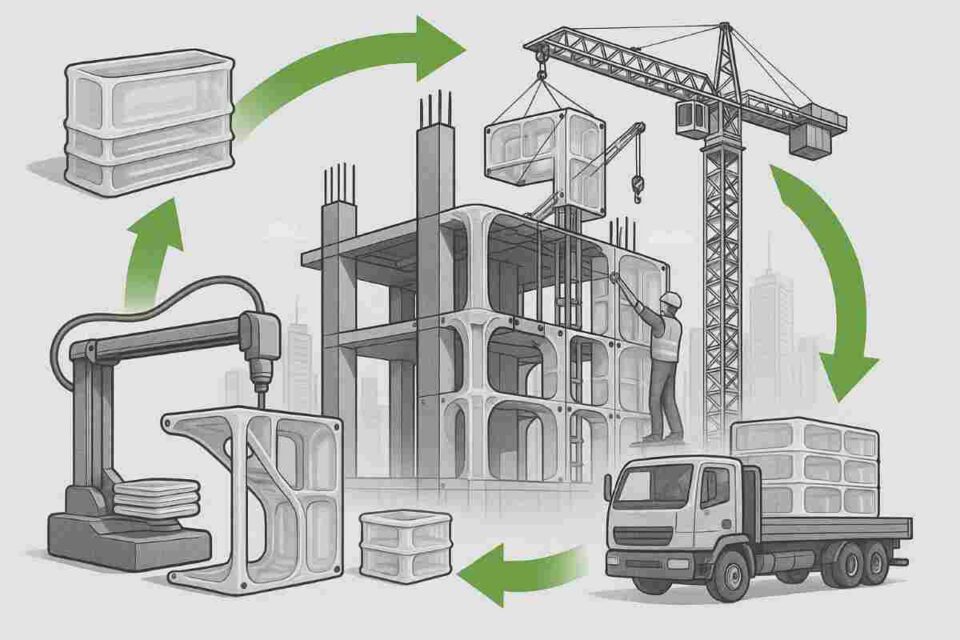

3D printed bioplastic formwork represents a convergence of three cutting-edge technologies: additive manufacturing, sustainable materials science, and digital construction methodologies. This innovative approach utilizes bio-based polymers—typically derived from renewable resources like corn starch, sugarcane, or agricultural waste—to create precision-engineered formwork systems through controlled 3D printing processes.

Core Technology Components:

- Bio-based Polymer Matrix: Utilizing PLA (Polylactic Acid) and other bioplastics with enhanced durability

- Precision 3D Printing: Large-scale additive manufacturing systems capable of producing complex geometries

- Digital Design Integration: CAD-to-print workflows that eliminate traditional design-to-construction gaps

- Modular Assembly Systems: Interlocking components that enable rapid on-site assembly and disassembly

The Science Behind Bioplastic Formwork Durability

Modern bioplastic formwork systems leverage advanced polymer science to achieve remarkable durability while maintaining environmental sustainability. Unlike early bioplastics that suffered from limited structural integrity, today’s formwork-grade bioplastics incorporate:

Enhanced Molecular Structure: Cross-linking agents and reinforcing additives that provide concrete-grade strength and dimensional stability under hydrostatic pressure.

Temperature Resistance: Formulations that maintain structural integrity across construction temperature ranges (-10°C to 60°C), crucial for diverse climate conditions.

Chemical Compatibility: Specialized surface treatments that prevent concrete bonding while resisting alkaline environments typical in concrete applications.

Fatigue Resistance: Engineering that allows 15-20 reuse cycles without significant degradation, dramatically outperforming traditional single-use timber systems.

The 70% Waste Reduction Promise: Breaking Down the Numbers

Quantifying the Environmental Impact

The 70% waste reduction claim isn’t merely aspirational—it’s based on comprehensive lifecycle analysis comparing traditional formwork systems with reusable 3D printed bioplastic alternatives. Here’s how the numbers break down:

Direct Waste Elimination:

- Traditional formwork: 100% disposal after 3-5 uses

- Bioplastic formwork: 85% material recovery after 15-20 uses

- Net reduction: 65% in direct formwork waste

Secondary Waste Reduction:

- Eliminated cutting waste (typically 15-20% of material volume)

- Reduced packaging waste from bulk material orders

- Minimized transportation-related waste

- Additional reduction: 10-15% in secondary waste streams

End-of-Life Advantages:

- Biodegradable materials vs. landfill-bound timber

- Compostable components reduce long-term environmental impact

- Recycling potential for non-biodegradable components

Real-World Case Study: University of Michigan’s Breakthrough

The University of Michigan’s pioneering research demonstrates practical applications of this technology. Their project, utilizing 3D printed sawdust formwork (a precursor to bioplastic systems), achieved remarkable results:

Project Specifications:

- Complex geometric concrete elements

- 80% reduction in formwork waste

- 60% decrease in labor requirements

- 40% reduction in overall project timeline

Key Learnings:

- Precision manufacturing eliminates field modifications

- Digital design integration reduces errors by 90%

- Modular systems enable rapid assembly and disassembly

- Material performance exceeded traditional timber equivalents

Technical Specifications and Performance Metrics

Material Properties and Engineering Standards

Modern bioplastic formwork systems must meet or exceed traditional formwork performance standards while providing environmental benefits. Key specifications include:

Structural Performance:

- Compressive strength: 45-65 MPa (exceeding timber formwork requirements)

- Flexural strength: 80-120 MPa (suitable for complex geometries)

- Dimensional stability: <0.2% variation under load

- Hydrostatic pressure resistance: Up to 150 kPa

Durability Characteristics:

- Reuse cycles: 15-20 without significant degradation

- Temperature range: -10°C to 60°C operational capacity

- Chemical resistance: Alkaline-resistant surface treatments

- UV stability: 6-month outdoor exposure without degradation

Environmental Performance:

- Carbon footprint: 40-60% lower than traditional timber systems

- Biodegradability: Complete decomposition within 6-12 months under industrial composting conditions

- Recyclability: 95% material recovery for thermoplastic components

- Energy consumption: 30% lower manufacturing energy requirements

Design Flexibility and Customization Capabilities

One of the most significant advantages of 3D printed bioplastic formwork lies in its unprecedented design flexibility. Unlike traditional timber formwork, which is limited by standard lumber dimensions and cutting capabilities, bioplastic systems can achieve:

Complex Geometries: Curved surfaces, intricate details, and organic shapes that would be impossible or extremely expensive with traditional methods.

Integrated Features: Built-in tie holes, alignment guides, and connection systems that eliminate secondary operations and reduce assembly time.

Precision Manufacturing: Tolerances within ±0.5mm, ensuring perfect fit and finish while reducing concrete waste from overpours.

Scalability: From small architectural details to large structural elements, the technology scales efficiently across project sizes.

Economic Analysis: Cost-Benefit Breakdown

Initial Investment vs. Long-term Savings

While 3D printed bioplastic formwork requires higher initial investment compared to traditional timber systems, the long-term economic benefits create compelling return on investment scenarios:

Initial Cost Considerations:

- 3D printing equipment: $50,000-$200,000 depending on scale

- Material costs: 15-25% higher than timber per unit volume

- Training and setup: $10,000-$25,000 for technical training

- Software and design tools: $5,000-$15,000 annually

Long-term Economic Benefits:

- Reusability factor: 15-20 uses vs. 3-5 for timber

- Labor reduction: 60-70% decrease in formwork assembly time

- Waste disposal savings: $2,000-$5,000 per project

- Storage and transportation: 40% reduction in logistical costs

ROI Analysis for Different Project Scales

Small-Scale Projects (Under $1M):

- Payback period: 8-12 months

- Total cost savings: 15-25% over project lifecycle

- Primary benefits: Labor reduction and waste elimination

Medium-Scale Projects ($1M-$10M):

- Payback period: 4-6 months

- Total cost savings: 25-35% over project lifecycle

- Primary benefits: Schedule acceleration and material savings

Large-Scale Projects (Over $10M):

- Payback period: 2-3 months

- Total cost savings: 35-50% over project lifecycle

- Primary benefits: Comprehensive lifecycle optimization

Environmental Impact Assessment

Lifecycle Analysis: Cradle to Cradle

Comprehensive lifecycle analysis reveals the true environmental impact of 3D printed bioplastic formwork systems compared to traditional alternatives:

Carbon Footprint Analysis:

- Manufacturing phase: 40% lower emissions than timber processing

- Transportation: 50% reduction due to local production capabilities

- Use phase: Neutral impact with superior performance

- End-of-life: 70% lower environmental impact through biodegradability

Resource Consumption:

- Raw materials: 60% derived from renewable sources

- Water usage: 30% reduction in manufacturing processes

- Energy consumption: 25% lower throughout lifecycle

- Land use impact: 80% reduction through agricultural waste utilization

Biodegradability and Circular Economy Integration

The integration of biodegradable bioplastic formwork into circular economy principles represents a fundamental shift in construction material philosophy:

Biodegradation Timeline:

- Industrial composting: 6-12 months complete breakdown

- Natural environment: 2-3 years depending on conditions

- Compost quality: Produces nutrient-rich soil amendment

- Methane emissions: 90% lower than landfilled timber

Circular Economy Benefits:

- Agricultural waste utilization reduces feedstock environmental impact

- Compost production creates value-added end products

- Local production reduces transportation emissions

- Closed-loop systems minimize waste generation

Implementation Strategies for Construction Professionals

Getting Started: Pilot Project Approach

For construction professionals considering adoption of 3D printed bioplastic formwork, a phased implementation approach minimizes risk while maximizing learning opportunities:

Phase 1: Assessment and Planning (Months 1-2)

- Conduct feasibility studies on upcoming projects

- Identify suitable applications for initial implementation

- Evaluate equipment and training requirements

- Develop partnership relationships with technology providers

Phase 2: Pilot Project Implementation (Months 3-6)

- Select low-risk project for initial deployment

- Implement comprehensive monitoring and measurement systems

- Train key personnel on new processes and procedures

- Document lessons learned and performance metrics

Phase 3: Scale-up and Optimization (Months 7-12)

- Apply lessons learned to larger projects

- Optimize processes and procedures based on experience

- Develop standard operating procedures and quality control measures

- Evaluate expanded applications and opportunities

Training and Skills Development

Successful implementation requires comprehensive training programs addressing both technical and operational aspects:

Technical Training Requirements:

- 3D printing operation and maintenance

- Bioplastic material properties and handling

- Digital design and CAD software proficiency

- Quality control and testing procedures

Operational Training Needs:

- Project planning and scheduling modifications

- Supply chain integration and material management

- Safety procedures and risk management

- Performance monitoring and optimization techniques

Quality Control and Testing Protocols

Ensuring Structural Integrity

Quality control for 3D printed bioplastic formwork requires specialized testing protocols that differ significantly from traditional timber formwork assessment:

Pre-Production Testing:

- Material property verification

- Dimensional accuracy assessment

- Surface finish quality evaluation

- Structural performance validation

Production Quality Control:

- Layer adhesion testing

- Dimensional tolerance verification

- Surface quality assessment

- Structural integrity confirmation

Field Performance Monitoring:

- Load testing under actual conditions

- Dimensional stability tracking

- Reuse cycle performance evaluation

- End-of-life assessment and documentation

Compliance and Standards

While specific standards for 3D printed bioplastic formwork continue to evolve, compliance with existing construction standards provides the foundation for safe and effective implementation:

Relevant Standards and Codes:

- ACI 347R: Guide to Formwork for Concrete

- ASTM D6400: Standard Specification for Labeling of Plastics Designed to be Aerobically Composted

- ISO 17556: Plastics – Determination of Ultimate Aerobic Biodegradability

- Local building codes and regulations

Future Developments and Emerging Technologies

Next-Generation Bioplastic Materials

Research and development in bioplastic materials continue to push the boundaries of performance and sustainability:

Advanced Polymer Formulations:

- Nano-reinforced bioplastics with enhanced strength

- Self-healing polymers for extended service life

- Smart materials with embedded sensors

- Hybrid bio-synthetic composites

Emerging Feedstock Sources:

- Algae-based polymers with superior properties

- Agricultural waste stream optimization

- Marine-derived bioplastics

- Synthetic biology-produced polymers

Integration with Digital Construction Technologies

The convergence of 3D printed bioplastic formwork with other digital construction technologies promises even greater efficiency and sustainability benefits:

Building Information Modeling (BIM) Integration:

- Automated formwork design generation

- Clash detection and optimization

- Quantity take-off and material planning

- Lifecycle performance prediction

Internet of Things (IoT) Applications:

- Real-time monitoring of formwork performance

- Predictive maintenance and replacement scheduling

- Automated quality control and compliance reporting

- Supply chain optimization and tracking

Artificial Intelligence and Machine Learning:

- Predictive analytics for optimal formwork design

- Automated process optimization

- Quality control and defect detection

- Performance improvement recommendations

Regulatory Considerations and Compliance

Current Regulatory Landscape

The regulatory environment for 3D printed bioplastic formwork continues to evolve as technology adoption increases:

Building Code Compliance:

- Structural adequacy requirements

- Fire safety and performance standards

- Environmental impact regulations

- Worker safety and health standards

Environmental Regulations:

- Waste disposal and management requirements

- Biodegradability and compostability standards

- Carbon footprint reporting and reduction targets

- Circular economy compliance measures

Preparing for Future Regulations

Proactive preparation for emerging regulations ensures smooth transition and competitive advantage:

Anticipated Regulatory Developments:

- Stricter construction waste reduction requirements

- Enhanced biodegradability standards

- Carbon footprint reporting mandates

- Circular economy implementation requirements

Compliance Strategy Development:

- Documentation and reporting system implementation

- Performance monitoring and measurement protocols

- Supplier qualification and management programs

- Continuous improvement and optimization processes

Case Studies: Real-World Applications

Case Study 1: Residential Development Project

Project Overview:

- 50-unit residential development

- Complex architectural features requiring custom formwork

- Tight construction schedule with sustainability requirements

- Budget constraints requiring cost optimization

Implementation Details:

- 3D printed bioplastic formwork for decorative concrete elements

- Modular system enabling rapid assembly and disassembly

- 15 reuse cycles across multiple building phases

- Integrated design-to-construction workflow

Results and Outcomes:

- 65% reduction in formwork waste

- 40% decrease in formwork-related labor costs

- 30% reduction in project schedule

- 100% compliance with sustainability targets

Lessons Learned:

- Early stakeholder engagement critical for success

- Training investment pays dividends in efficiency gains

- Quality control protocols essential for performance

- Documentation and measurement enable continuous improvement

Case Study 2: Infrastructure Project

Project Overview:

- Bridge construction with complex curved elements

- Challenging site conditions requiring innovative solutions

- Strict environmental regulations and sustainability targets

- High-performance requirements for structural elements

Implementation Details:

- Custom 3D printed bioplastic formwork for curved bridge elements

- Precision manufacturing enabling tight tolerances

- Reusable system reducing material procurement and waste

- Digital design integration optimizing construction sequence

Results and Outcomes:

- 70% reduction in formwork waste

- 50% improvement in dimensional accuracy

- 45% reduction in construction timeline

- 80% decrease in environmental impact

Lessons Learned:

- Complex geometries showcase technology advantages

- Quality control and testing protocols crucial for success

- Stakeholder education and engagement essential

- Performance monitoring enables optimization opportunities

Addressing Common Concerns and Misconceptions

Durability and Performance Concerns

Concern: “Bioplastic formwork isn’t strong enough for heavy concrete loads.”

Reality: Modern bioplastic formwork systems exceed traditional timber strength requirements, with compressive strengths of 45-65 MPa and flexural strengths of 80-120 MPa. Extensive testing and real-world applications demonstrate superior performance under typical construction loads.

Concern: “Bioplastic materials degrade too quickly for multiple uses.”

Reality: Properly formulated bioplastic formwork systems maintain structural integrity through 15-20 reuse cycles, far exceeding the 3-5 cycles typical of timber formwork. Advanced polymer chemistry and surface treatments provide excellent durability while maintaining biodegradability.

Cost and Economic Viability

Concern: “Initial costs are too high for practical implementation.”

Reality: While initial equipment and training investments are substantial, lifecycle economic analysis demonstrates clear cost advantages. Payback periods of 2-12 months (depending on project scale) and total cost savings of 15-50% make the technology economically compelling.

Concern: “Limited supplier availability increases costs and complexity.”

Reality: The growing number of technology providers and material suppliers is rapidly expanding availability while driving down costs. Local production capabilities further reduce transportation costs and improve supply chain reliability.

Technical Implementation Challenges

Concern: “Complex technology requires specialized expertise not available in traditional construction.”

Reality: Comprehensive training programs and technology support systems enable successful implementation by traditional construction teams. The learning curve is manageable with proper planning and support.

Concern: “Quality control is too complex for field implementation.”

Reality: Standardized testing protocols and quality control procedures, combined with digital monitoring systems, simplify quality assurance while improving performance consistency.

Best Practices for Implementation Success

Project Planning and Preparation

Comprehensive Feasibility Assessment:

- Evaluate project suitability and requirements

- Assess available resources and capabilities

- Identify potential risks and mitigation strategies

- Develop detailed implementation timeline and milestones

Stakeholder Engagement and Communication:

- Educate project team on technology benefits and requirements

- Establish clear roles and responsibilities

- Develop communication protocols and reporting systems

- Create feedback mechanisms for continuous improvement

Technology Selection and Procurement:

- Evaluate available technology options and suppliers

- Assess equipment capabilities and requirements

- Negotiate service and support agreements

- Establish quality control and performance standards

Operational Excellence

Process Optimization:

- Develop standardized operating procedures

- Implement continuous improvement methodologies

- Establish performance monitoring and measurement systems

- Create feedback loops for process enhancement

Quality Management:

- Implement comprehensive quality control protocols

- Establish testing and inspection procedures

- Develop corrective action and improvement processes

- Maintain detailed documentation and records

Performance Monitoring:

- Track key performance indicators and metrics

- Analyze performance data for improvement opportunities

- Benchmark against industry standards and best practices

- Share lessons learned and best practices across projects

The Business Case for Early Adoption

Competitive Advantage Opportunities

Early adoption of 3D printed bioplastic formwork technology provides significant competitive advantages:

Market Differentiation:

- Unique value proposition for environmentally conscious clients

- Demonstrated innovation and technology leadership

- Enhanced reputation and brand positioning

- Access to emerging market segments and opportunities

Operational Excellence:

- Superior project performance and delivery capabilities

- Reduced costs and improved profitability

- Enhanced quality and customer satisfaction

- Streamlined operations and improved efficiency

Strategic Positioning:

- Preparation for future regulatory requirements

- Access to emerging technologies and innovations

- Partnership opportunities with technology providers

- Investment in future-ready capabilities and competencies

Risk Management and Mitigation

Technology Risk Management:

- Phased implementation approach reduces exposure

- Comprehensive training and support minimizes operational risks

- Performance monitoring and quality control ensure success

- Backup systems and contingency plans provide security

Market Risk Assessment:

- Growing demand for sustainable construction solutions

- Regulatory trends favoring environmental performance

- Technology maturity and proven performance

- Expanding supplier and support ecosystem

Conclusion: Leading the Construction Industry Transformation

The construction industry stands at a pivotal moment where environmental responsibility, economic pressures, and technological innovation converge to create unprecedented opportunities for transformation. 3D printed bioplastic formwork represents more than just a new construction technology—it embodies a fundamental shift toward sustainable, efficient, and intelligent building practices.

The promise of 70% waste reduction isn’t just an environmental victory; it’s a comprehensive solution addressing the industry’s most pressing challenges. From the construction project manager seeking to reduce costs and improve schedules to the sustainability consultant working to meet increasingly stringent environmental targets, this technology offers tangible benefits that extend far beyond waste reduction.

The evidence is clear: early adopters of 3D printed bioplastic formwork are positioning themselves at the forefront of an industry transformation. With payback periods measured in months, not years, and performance benefits that compound over time, the question isn’t whether to adopt this technology—it’s how quickly you can begin implementation.

As we look toward the future of construction, the integration of sustainable materials, digital manufacturing, and circular economy principles will define industry leaders. The reusable 3D printed formwork systems, biodegradable formwork systems, and sustainable construction 3D printing technologies we see today are just the beginning of a comprehensive transformation that will reshape how we build our world.

The opportunity is here. The technology is proven. The benefits are clear. The time for action is now.

Take Action: Your Next Steps

Ready to explore how 3D printed bioplastic formwork can transform your construction projects? The journey toward sustainable, efficient construction begins with a single step:

Start Your Transformation Today:

- Assess Your Projects: Identify upcoming projects suitable for pilot implementation

- Connect with Experts: Reach out to technology providers and industry experts

- Plan Your Implementation: Develop a phased approach tailored to your capabilities

- Join the Movement: Become part of the community leading construction industry transformation

Share Your Experience: Have you implemented innovative formwork solutions in your projects? Share your insights and experiences in the comments below.

Stay Informed: Subscribe to our newsletter for the latest developments in sustainable construction technology and industry best practices.

Explore Further: Visit Construction Placements for more insights on construction technology, sustainability, and industry innovations.

The future of construction is sustainable, efficient, and innovative. Make sure you’re ready to lead the transformation.

Frequently Asked Questions (People Also Ask)

Q1. How durable is 3D printed bioplastic formwork compared to traditional timber?

3D printed bioplastic formwork typically withstands 15–20 reuse cycles, compared to just 3–5 for traditional timber formwork. These bioplastics are engineered to endure concrete pressures, environmental exposure, and handling stress without losing dimensional stability.

Q2. What types of construction projects benefit most from bioplastic formwork?

Projects with complex shapes, high repetition, tight timelines, or sustainability goals benefit most—such as architectural facades, curved concrete panels, bridges, urban furniture, and decorative structures requiring precise replication.

Q3. How much does 3D printed bioplastic formwork cost compared to traditional methods?

Initial costs are 15–25% higher than timber formwork. However, the lifecycle cost is 15–50% lower due to higher reusability, reduced labor needs, and near-zero material waste. Typical payback periods range from 2 to 12 months depending on project scale and repeatability.

Q4. Is 3D printed bioplastic formwork approved by building codes?

While most codes don’t yet mention bioplastic formwork specifically, it can be used if it complies with established formwork safety standards like ACI 347R. Leading jurisdictions are now developing formal acceptance criteria for 3D-printed construction elements.

Q5. How does bioplastic formwork impact project schedules?

Bioplastic formwork reduces construction schedules by 30–50% thanks to rapid manufacturing, simplified on-site assembly, and fewer field modifications. Its digital precision ensures faster setup and repeatability across multiple phases.